Exploring Trends in Electronic Board Assembly at the 138th Canton Fair 2025: Industry Insights

As the 138th Canton Fair prepares to open its doors in 2025, the spotlight is set on the rapidly evolving field of electronic board assembly. This significant event will gather industry leaders, innovators, and manufacturers to showcase their latest advancements and trends in this crucial sector.

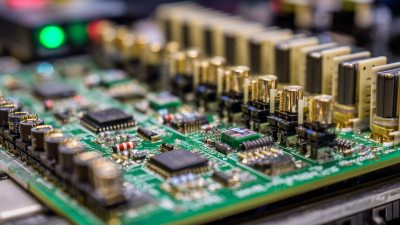

Electronic board assembly, a foundational component of modern electronics, is witnessing transformative changes driven by technological advancements, sustainability demands, and the increasing complexity of consumer electronics.

Participants at the fair will explore cutting-edge techniques, materials, and automation processes that enhance efficiency and product quality. This introduction aims to provide a comprehensive overview of the current landscape of electronic board assembly, highlighting key trends and insights that will shape the future of the industry as revealed through discussions and exhibitions at this prestigious international trade platform.

Electronic board assembly, a foundational component of modern electronics, is witnessing transformative changes driven by technological advancements, sustainability demands, and the increasing complexity of consumer electronics.

Participants at the fair will explore cutting-edge techniques, materials, and automation processes that enhance efficiency and product quality. This introduction aims to provide a comprehensive overview of the current landscape of electronic board assembly, highlighting key trends and insights that will shape the future of the industry as revealed through discussions and exhibitions at this prestigious international trade platform.

Trends in Automation Technologies for Electronic Board Assembly at the Canton Fair 2025

At the 138th Canton Fair in 2025, the spotlight on electronic board assembly is set to unveil groundbreaking trends, particularly in automation technologies. As the industry evolves, automation is proving to be a game-changer, enhancing efficiency and precision in manufacturing processes.

Companies are increasingly integrating intelligent robotics and AI-driven solutions that streamline assembly lines, reduce human error, and improve product quality.

At the 138th Canton Fair in 2025, the spotlight on electronic board assembly is set to unveil groundbreaking trends, particularly in automation technologies. As the industry evolves, automation is proving to be a game-changer, enhancing efficiency and precision in manufacturing processes.

Companies are increasingly integrating intelligent robotics and AI-driven solutions that streamline assembly lines, reduce human error, and improve product quality.

Tips: When considering automation solutions, assess your specific assembly needs and look for technology that integrates seamlessly with your existing systems. Collaborating with tech providers during trade fairs can lead to tailored solutions that maximize your operational efficiency.

The Canton Fair 2025 will highlight these advancements, providing a platform for suppliers to showcase innovative products. Attendees can expect demonstrations of the latest automated systems that are designed to elevate electronic board assembly, setting a new standard for speed and reliability in production. By embracing these trends, businesses can stay competitive in an ever-evolving marketplace.

Tips: Engage with industry experts at the fair to gain insights into the practical applications of automation technologies. Networking with peers can also provide valuable feedback on what solutions have proven effective in real-world settings.

Emerging Materials and Their Impact on Electronic Board Assembly Efficiency in 2025

The 138th Canton Fair 2025 serves as a pivotal platform for professionals in the electronic board assembly industry to uncover emerging materials that significantly enhance operational efficiency. With advances in lightweight composites and high-performance laminates, manufacturers are witnessing improved thermal management and durability in assembly processes. These materials not only reduce the overall weight of electronic devices but also facilitate faster production speeds, ultimately contributing to a more sustainable manufacturing environment.

Tips: To stay ahead in the electronic board assembly landscape, consider investing in training for your team on the latest material technologies. Integration of such materials requires a skilled workforce that understands their unique properties and handling requirements. Regular workshops can boost proficiency, ensuring the effective implementation of these innovations.

Furthermore, the adoption of eco-friendly materials is gaining traction, as industry players strive to mitigate environmental impact. Biodegradable substrates and recycled components are making headway, reflecting a collective commitment to sustainability. By prioritizing green alternatives, businesses can not only enhance their reputation but also meet the growing consumer demand for environmentally responsible products.

Tips: Keep an eye on regulatory changes regarding material usage and environmental standards. Establishing a proactive approach to compliance can streamline your operations and provide a competitive advantage in the marketplace. Networking during events like the Canton Fair can yield valuable contacts and insights into best practices in sustainable manufacturing.

Market Analysis: Demand for Smart Electronics Driving Assembly Innovations at the Fair

The 138th Canton Fair in 2025 spotlighted the surging demand for smart electronics, significantly reshaping trends in electronic board assembly. As industries pivot towards automation and connectivity, manufacturers are responding by innovating their assembly processes to accommodate the increasing complexity of smart devices. This trend reflects not only an increase in product offerings but also a push towards sustainable practices, as companies seek to optimize efficiency and reduce waste in assembly lines.

Exhibitors at the fair showcased cutting-edge technologies that integrate artificial intelligence and robotics into assembly workflows. This advancement allows for real-time monitoring and quality assurance, thereby enhancing product reliability. Additionally, the growing interest in Internet of Things (IoT) devices has necessitated a focus on modular designs and flexible assembly systems, enabling swift adjustments to meet consumer demands. As smart electronics continue to proliferate, the assembly industry is poised for unprecedented transformations driven by innovation and heightened consumer expectations.

Sustainability Practices in Electronic Board Assembly Highlighted at the 138th Canton Fair

The 138th Canton Fair in 2025 showcased a significant emphasis on sustainability practices in electronic board assembly, reflecting the industry's growing commitment to environmental responsibility. As global awareness of ecological issues continues to rise, manufacturers are increasingly adopting greener methods throughout the assembly process. This includes the implementation of energy-efficient machinery, reduction of hazardous materials, and the use of recyclable components, all aimed at minimizing the ecological footprint of electronic products.

Another noteworthy trend observed at the fair was the integration of sustainable supply chain practices among exhibitors. Companies demonstrated their efforts to source materials responsibly and collaborate with suppliers who share similar sustainability goals. These initiatives not only contribute to a healthier planet but also resonate with consumers who prefer products that are ethically produced. As such, the fair served as a platform for industry players to exchange best practices and innovations that address sustainability challenges, reinforcing the notion that environmental stewardship is now a crucial aspect of electronic board assembly.

Exploring Trends in Electronic Board Assembly at the 138th Canton Fair 2025

| Trend | Description | Sustainability Practice | Impact on Industry |

|---|---|---|---|

| Automation Integration | Increased use of robotics to enhance efficiency. | Reduction of material waste through precise automation. | Boosts production speed and lowers costs. |

| Eco-Friendly Materials | Adoption of biodegradable and recyclable materials. | Minimizes environmental impact of electronic waste. | Encourages consumer acceptance and brand loyalty. |

| Advanced PCB Designs | Focus on high-density interconnections and miniaturization. | Less material usage and improved energy efficiency. | Enhances product performance and durability. |

| Renewable Energy Sources | Utilization of solar and wind energy in production processes. | Reduces carbon footprint and dependence on fossil fuels. | Positions companies as leaders in sustainability. |

Future Workforce Skills for the Electronic Board Assembly Industry: Insights from 2025 Expo

As we look towards the 2025 Expo, the future workforce skills needed in the electronic board assembly industry are rapidly evolving in response to technological advancements. The McKinsey Technology Trends Outlook 2025 highlights the anticipated impact of robotics and automation, projecting significant investment from industrial companies. This transformation necessitates a workforce skilled in advanced robotics programming, system integration, and maintenance of automated systems, which are becoming fundamental to efficient electronic manufacturing processes.

Furthermore, the trend towards digitalization in manufacturing is reshaping operational frameworks, as outlined in the latest industry reports. The global electronic manufacturing services market, valued at USD 626.8 billion in 2024, is expected to grow at a 5.1% CAGR from 2025 to 2034. This growth underscores the importance of equipping professionals with digital skills, such as data analysis and AI application, to enhance productivity and improve customer experiences in an increasingly competitive landscape. As companies transition to a skills-based workforce model, prioritizing continuous learning and adaptability will be essential for preparing employees for the challenges ahead in the electronic board assembly sector.

Trends in Electronic Board Assembly Skills in 2025

This chart illustrates the emerging workforce skills critical for the Electronic Board Assembly industry as identified during the 138th Canton Fair in 2025. The skills are categorized into five key areas, showcasing the importance of technology adaptation, quality control, and soft skills.

Related Posts

-

Innovative Examples of Printed Circuit Assembly that Set the Industry Standard

-

Unleashing the Power of Chinese Manufacturing in the Best PCB Production

-

Ultimate Checklist for Selecting the Best PCB Fabrication Services Worldwide

-

10 Essential PCB Printing Techniques You Need to Know

-

How to Achieve High Quality in Electronic Board Assembly Process

-

5 Best Strategies for Optimizing PCB Manufacturing Assembly Efficiency