Top Trends in Circuit Board Assembly for 2025 What You Need to Know

As we approach 2025, the realm of circuit board assembly is poised for transformative advancements that promise to reshape the landscape of electronics manufacturing. According to Dr. Emily Chen, a leading expert in the field, "The future of circuit board assembly will be defined by automation, precision, and sustainability, enabling manufacturers to meet the growing demands of a tech-savvy world." Her insights highlight the critical trends that will not only enhance efficiency but also align with environmental considerations.

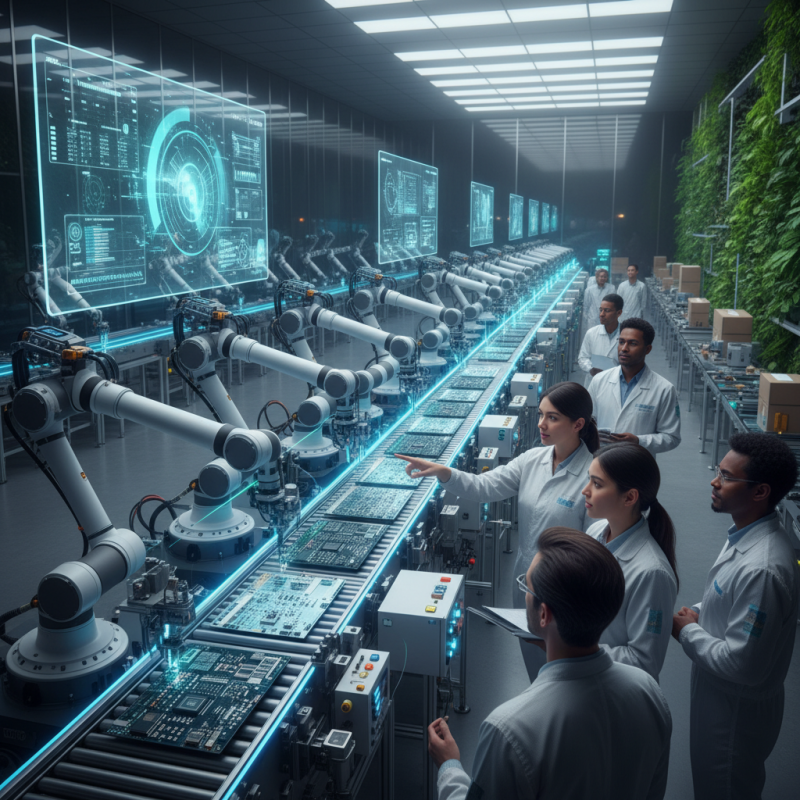

The industry is witnessing a surge in innovative technologies that emphasize smart manufacturing and reduced human intervention. From artificial intelligence algorithms optimizing assembly line processes to eco-friendly materials being prioritized in production, understanding these trends is essential for professionals aiming to stay ahead in the circuit board assembly sector. As the market evolves, businesses that harness these developments will ultimately gain a competitive advantage.

In this article, we will explore the top trends shaping circuit board assembly for 2025, focusing on key areas such as automation, sustainability, and technological integrations that redefine traditional practices. Staying informed about these trends is crucial for stakeholders looking to adapt and thrive in a rapidly changing industry landscape.

Emerging Technologies Shaping Circuit Board Assembly in 2025

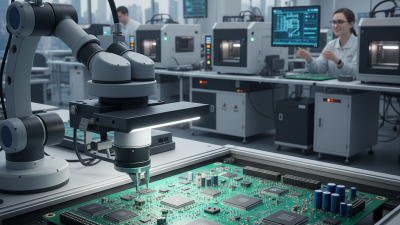

As we move toward 2025, several emerging technologies are set to revolutionize circuit board assembly (CBA), driving efficiency and innovation in the industry. One of the most significant trends is the adoption of advanced automation techniques. According to a recent market analysis, the global market for automated assembly equipment is projected to grow at a compound annual growth rate (CAGR) of over 10% by 2025. This growth is largely driven by the decreasing cost of robotics and the increasing need for precision and speed in assembling complex circuit boards.

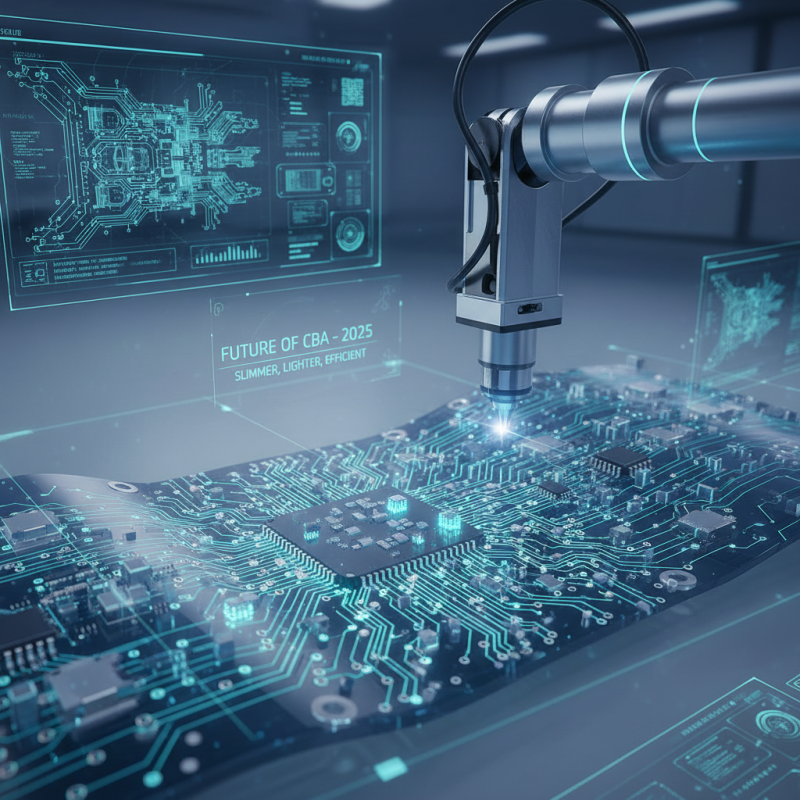

Another game-changing technology is the rise of flexible and printed electronics. This innovation allows for thinner, lighter, and more adaptable circuit designs, which are essential for next-generation devices in industries like consumer electronics and healthcare. A report from a leading research firm highlights that the flexible electronics market is expected to reach USD 40 billion by 2025, indicating a significant shift in how circuit boards are designed and integrated into products. The ability to produce circuit boards that can bend and conform to various shapes presents new opportunities for product design, ultimately enhancing consumer experiences.

Moreover, the integration of the Internet of Things (IoT) within the assembly process is increasingly evident. IoT-enabled machines can collect and analyze real-time data to improve production workflows and reduce downtime. An industry survey shows that companies implementing IoT technology in their CBA processes can achieve up to a 20% increase in operational efficiency, showcasing the potential for smarter manufacturing practices. The intersection of these technologies is set to define circuit board assembly in 2025, pushing the boundaries of what is currently possible in the electronics manufacturing landscape.

Sustainability Practices in Circuit Board Manufacturing and Assembly

Sustainability is becoming a central focus in the circuit board manufacturing and assembly industry as companies recognize the importance of environmentally friendly practices. One significant trend is the adoption of eco-friendly materials that minimize environmental impact. Manufacturers are increasingly using bioplastics and recycled materials in their circuit boards, which not only reduce waste but also lower carbon footprints. This shift is driven by both regulatory pressures and consumer demand for greener products, leading to innovative solutions that prioritize sustainability without compromising quality.

Additionally, the implementation of advanced manufacturing technologies is enhancing sustainability efforts. Techniques such as additive manufacturing and automated assembly processes help reduce material waste and energy consumption during production. By optimizing supply chains and incorporating energy-efficient machinery, manufacturers can achieve a significant reduction in their overall environmental impact. Furthermore, organizations are now placing a greater emphasis on lifecycle assessments, which evaluate the environmental impact of circuit boards from production to disposal, ensuring that sustainability is integrated at every stage of the product lifecycle. This comprehensive approach not only aligns with global sustainability goals but also enhances the long-term viability of the circuit board industry.

Automation and Robotics: The Future of PCB Assembly Processes

The landscape of circuit board assembly (CBA) is evolving rapidly as we approach 2025, with automation and robotics playing a pivotal role. According to recent industry reports, automation in PCB assembly processes is projected to increase productivity by up to 50% while simultaneously reducing operational costs. This shift is driven by the necessity for faster production cycles and the growing complexity of electronic devices. The use of advanced robotics enables manufacturers to achieve precision and consistency, thereby minimizing human error and enhancing overall quality.

As automation technologies become more accessible, manufacturers must also adapt to utilizing smart machinery and IoT capabilities. Real-time monitoring systems and data analytics are now integral in optimizing assembly lines, facilitating predictive maintenance, and ensuring that production meets the ever-changing demands of the market. A study by the Semiconductor Industry Association indicates that companies embracing automation see a return on investment within just 18 months, highlighting its economic viability.

Tip: When considering the integration of automation in PCB assembly, start with a pilot project focusing on a specific process. This allows for evaluating the technology’s effectiveness before a full-scale rollout.

The rise of collaborative robots, or cobots, represents another significant trend in PCB assembly. These machines work alongside human operators to enhance assembly tasks without replacing the workforce. According to a report from the International Federation of Robotics, the utilization of collaborative robots in manufacturing is expected to grow by 40% annually. This trend not only boosts efficiency but also creates a safer working environment, allowing human workers to focus on more complex tasks.

Tip: Invest in training for your employees to work alongside these new technologies, enhancing their skills while fostering a culture of innovation in your organization.

Design Innovations in Circuit Board Assembly for Enhanced Performance

In 2025, the landscape of circuit board assembly (CBA) is set to undergo significant transformations driven by innovative design strategies aimed at enhancing performance. One key trend is the integration of advanced materials such as flexible substrates and high-density interconnects (HDI), which are enabling manufacturers to create slimmer, lighter, and more efficient circuit boards. According to a recent industry report, the global HDI market is projected to grow at a compound annual growth rate (CAGR) of 12% from 2023 to 2028, underscoring the increasing reliance on these technologies for high-performance applications.

Another prominent design innovation is the adoption of modular assembly techniques, which allow for more flexible manufacturing processes. This approach not only simplifies the assembly process but also enhances scalability and repairability. The industry's shift towards modular designs is expected to reduce production time by up to 25%, while improving overall product reliability. Furthermore, the embrace of automation and artificial intelligence in circuit board assembly processes is anticipated to yield improvements in precision, reducing error rates to less than 1%. This convergence of design innovations in CBA is essential for meeting the evolving demands of sectors such as automotive and telecommunications, which are increasingly reliant on robust and efficient electronic solutions.

Market Trends and Predictions for Circuit Board Assembly in 2025

As we look toward 2025, the circuit board assembly market is poised to undergo significant transformations driven by advancements in technology and evolving consumer demands. One of the most noteworthy trends is the increasing integration of automation within assembly processes. Manufacturers are leveraging robotics and artificial intelligence to enhance precision and efficiency, which not only reduces production times but also minimizes the potential for human error. This shift toward automation is particularly impactful in high-volume production settings where scalability and speed are critical.

Another trend shaping the landscape of circuit board assembly is the growing emphasis on sustainability. As environmental concerns continue to rise, manufacturers are seeking eco-friendly materials and processes to reduce their carbon footprint. This includes the adoption of lead-free solder and recyclable components, as well as optimization of energy usage during production. The trend towards greener practices is not just about compliance; it also resonates with consumers who are increasingly favoring companies committed to environmental stewardship.

Furthermore, the demand for customized and complex circuit boards is expected to increase. As various industries, including automotive and healthcare, require more sophisticated electronics, companies will need to adapt their assembly processes to accommodate these specific needs. This may involve investing in advanced technologies such as 3D printing and flexible circuit designs, which allow for greater innovation and customization in the products offered. These market trends will likely redefine the circuit board assembly landscape, making 2025 a pivotal year for industry players.

Related Posts

-

Navigating Import Export Certifications for Best Electronic Board Assembly Suppliers

-

The Ultimate Guide to Mastering Circuit Board Assembly Techniques for Success

-

Why PCB Assembly is Critical for Your Electronics Manufacturing Success

-

Unleashing the Power of Chinese Manufacturing in the Best PCB Production

-

Emerging Trends in Circuit Board Design for 2025: Innovating for the Future

-

How to Optimize Your Electronic Board Assembly Process for Maximum Efficiency