Understanding Product Features and Applications in Best PCB Manufacturing and Assembly

In the rapidly evolving world of electronics, the significance of understanding product features and applications in the context of PCB manufacturing and assembly cannot be overstated. As businesses strive to create innovative and reliable electronic devices, the role of printed circuit boards (PCBs) has become increasingly critical. This ultimate guide aims to demystify the intricate processes involved in PCB manufacturing and assembly, offering insights into key factors that influence design choices, functionality, and production efficiency. By exploring the various features and applications of PCBs, manufacturers can better navigate the complexities of modern technology, ensuring that their products not only meet industry standards but also cater to the unique needs of their customers. Whether you are a seasoned professional or new to the field, this comprehensive resource will equip you with the essential knowledge to make informed decisions in PCB manufacturing and assembly.

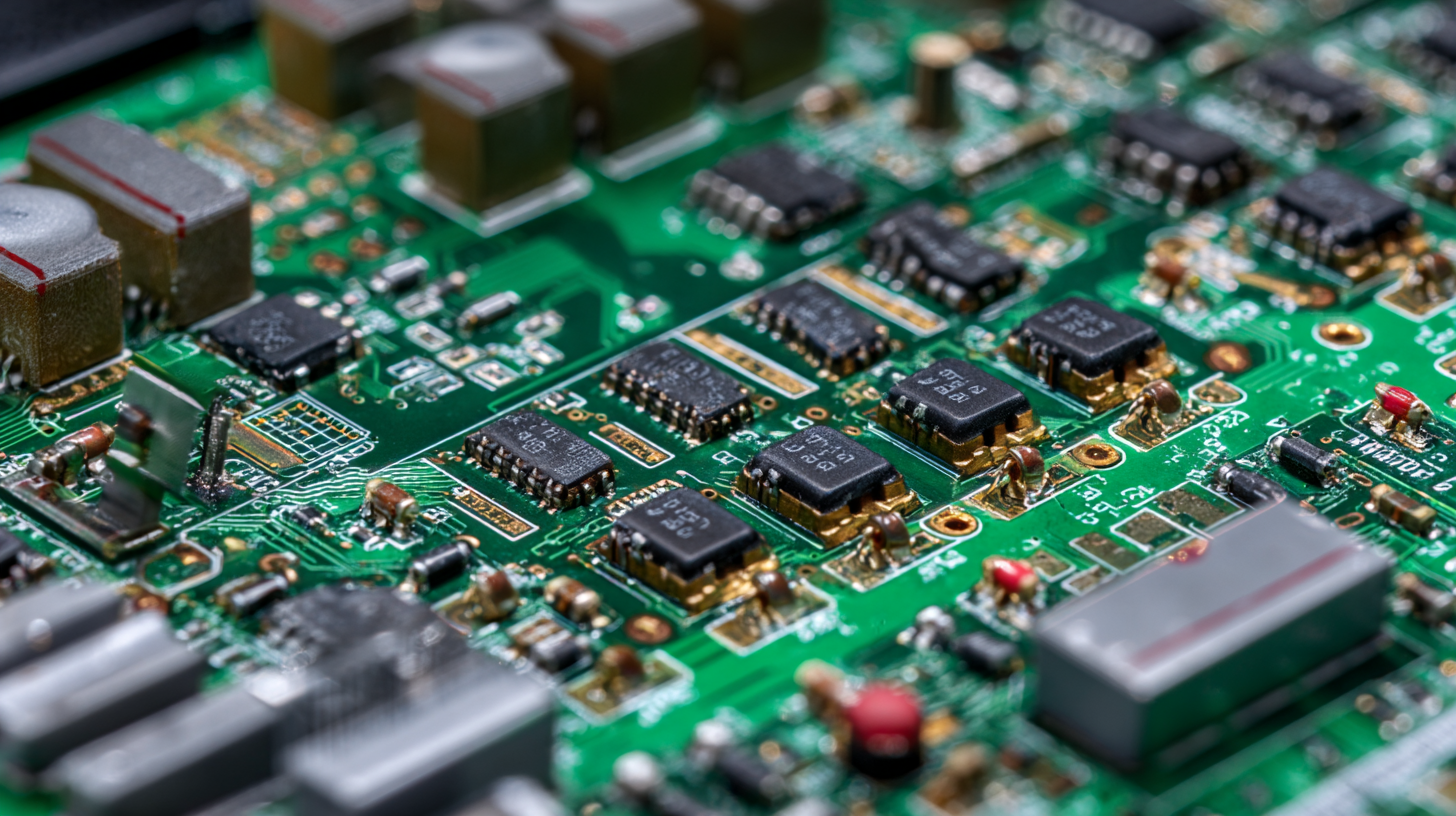

Key Characteristics of High-Quality PCBs from Leading Chinese Manufacturers

When selecting high-quality printed circuit boards (PCBs) from leading Chinese manufacturers, several key characteristics stand out.

Firstly, the use of advanced materials such as high-grade FR-4 and low-loss materials significantly enhances the performance and reliability of PCBs.

These materials ensure that the boards can withstand higher temperatures and provide better dielectric properties, which are essential for high-speed applications.

Additionally, leading manufacturers often utilize state-of-the-art manufacturing techniques, including automated optical inspection (AOI) and robotic assembly, to ensure precision and consistency throughout the production process.

Another defining feature of top-tier PCBs is their adherence to international quality standards, such as IPC and ISO certifications.

These standards guarantee that the PCBs meet stringent performance metrics and enhance their durability, making them suitable for various applications ranging from consumer electronics to industrial machinery.

Furthermore, leading Chinese manufacturers often offer customization options, allowing clients to specify dimensions, layer counts, and surface finishes that cater to the specific needs of their projects.

This flexibility, coupled with competitive pricing and shorter lead times, positions these manufacturers as reliable partners in the global electronics market.

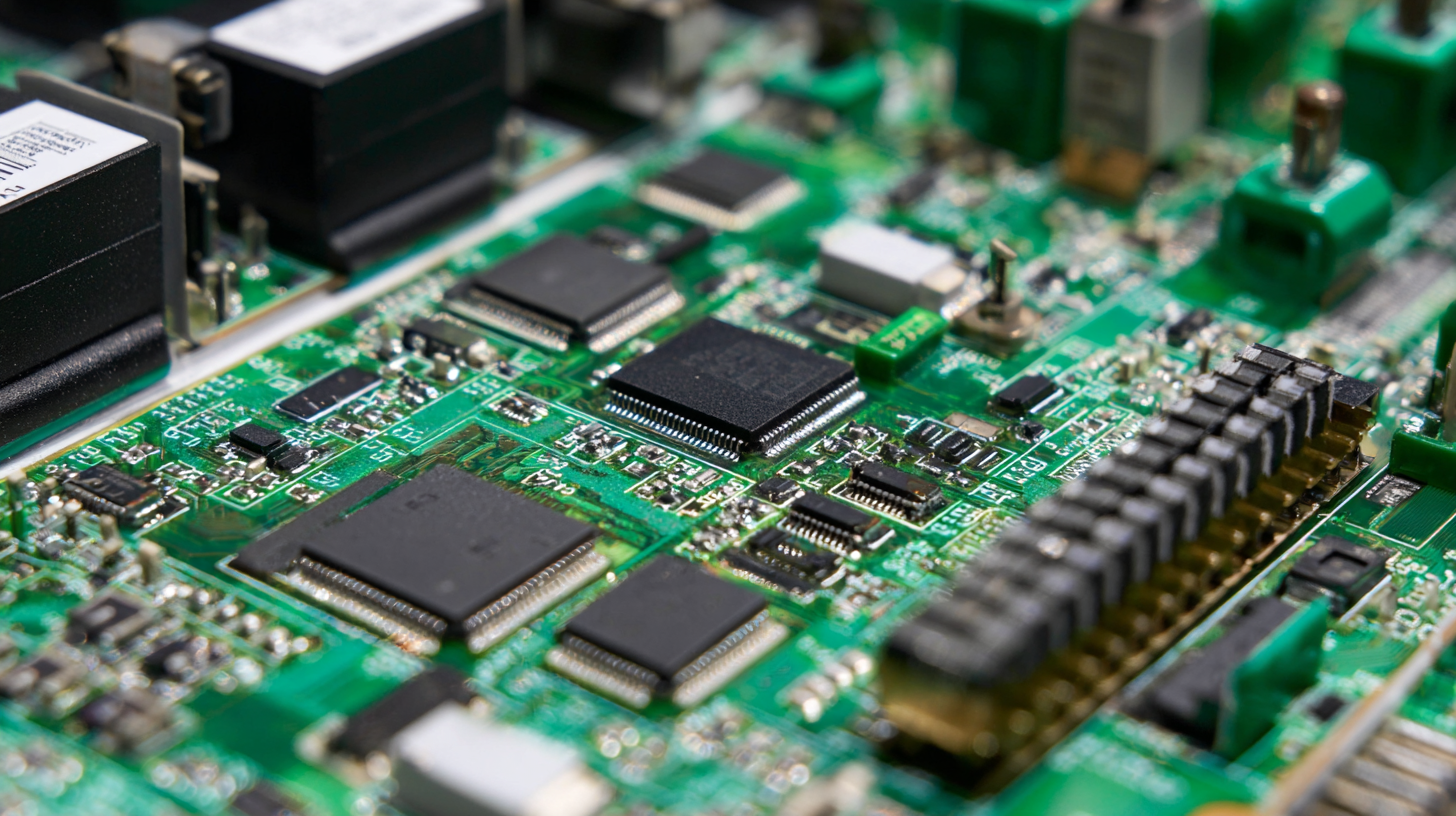

Innovative Applications of PCBs Across Various Industries

The printed circuit board (PCB) industry is experiencing remarkable growth, driven by innovative applications across diverse sectors. In recent years, the market for PCBs, including rigid boards, flexible circuits, and HDI boards, has expanded significantly, with a notable compound annual growth rate (CAGR) anticipated for the coming years. Applications in automotive, consumer electronics, telecommunications, and healthcare are among the key drivers of this growth, showcasing the versatility of PCBs in modern technology.

As industries increasingly integrate advanced technologies like AI and quantum computing, the demand for PCBs has surged. These innovations not only enhance product performance but also improve production efficiency, making PCBs critical to future advancements in electronics. The rising prominence of smart devices and connectivity solutions further solidifies the essential role of PCBs in various applications, contributing to a robust and dynamic marketplace projected to reach new heights by 2032. Continued investments and technological developments are set to propel the industry into a new era of innovation.

The Role of Advanced Technology in PCB Manufacturing Excellence

The role of advanced technology in PCB manufacturing excellence cannot be understated, especially in an era where digital transformation is driving operational effectiveness. Industry leaders are adopting innovative technologies to enhance efficiencies, allowing for streamlined production processes and more reliable product outcomes. For instance, recent initiatives in Gujarat, which include strong support for research and development in electronics, highlight how strategic investments can bolster technological advancements in PCB manufacturing.

To achieve excellence in high-current PCB design, consider these tips: First, focus on optimizing your layout to manage thermal and electrical performance effectively. Use advanced simulation tools to predict performance outcomes before moving to production. Second, ensure robust material selection, prioritizing options that can withstand high currents without compromising integrity. Lastly, continually update your knowledge on emerging technologies and methodologies, as staying ahead in the competitive landscape of electronics manufacturing can significantly impact your product's success.

As companies like NMTronics and various educational institutions collaborate to establish centers of excellence, the future of PCB manufacturing looks promising. By incorporating cutting-edge technologies and fostering educational partnerships, the industry is set to meet rising demands while ensuring sustainability and efficiency in operations.

Quality Control Processes in Best PCB Assembly Practices

In the competitive landscape of PCB manufacturing and assembly, quality control processes are crucial for ensuring that products meet rigorous industry standards. According to a report by IPC, nearly 45% of companies have reported that implementing effective quality control measures can reduce production errors by up to 30%. This highlights the importance of meticulous inspection and adherence to industry specifications throughout the assembly process.

One effective quality control strategy is the use of automated Optical Inspection (AOI) systems, which can identify defects and inconsistencies in real-time. In fact, studies suggest that AOI systems can increase defect detection rates by more than 70%, leading to significantly improved product reliability. Furthermore, regular audits and staff training on quality standards are essential for maintaining a high level of craftsmanship in PCB assembly.

**Tip:** Incorporating a robust feedback loop from production teams can enhance the effectiveness of your quality control measures. Engaging employees in identifying potential quality issues can lead to continuous improvement.

Another key aspect in quality control is the implementation of rigorous testing protocols, such as Functional Testing and In-Circuit Testing (ICT). These tests help to confirm that the PCB performs as intended under various conditions. A recent survey indicated that 60% of companies that implemented comprehensive testing protocols saw a reduction in customer returns by up to 40%.

**Tip:** Regularly reviewing and updating testing protocols can ensure that they align with the latest industry standards and technological advancements.

Understanding PCB Manufacturing Quality Control Processes

This bar chart illustrates key quality control metrics in PCB manufacturing and assembly. Key metrics include defect rates, test coverage, yield rates, cycle time, and cost per unit, providing a comprehensive overview of the quality standards in PCB production.

Understanding Market Trends in PCB Features and Consumer Demands

The demand for silicon chips is rapidly increasing, fueling market growth in various sectors. Silicon-based nanotechnology, particularly in the realm of chips, has found its way into a plethora of devices. These include implantable electronic devices, wearables, and flexible displays, which represent the forefront of modern technology. As consumers lean towards more advanced electronic solutions, manufacturers are compelled to innovate and address these shifting demands by enhancing product features.

In the automotive sector, the PCB market is on track to expand significantly. From a valuation of $9.15 billion in 2023, it is projected to swell to $15.1 billion by 2032, showcasing a compound annual growth rate of 5.9%. This growth can be attributed to the rising integration of advanced electronics in vehicles, focusing on safety and efficiency. Additionally, the Bismaleimide triazine BT resin market is expected to experience substantial growth as well, increasing from $12 million in 2022 to $20 million by 2030 at a CAGR of 7.0%. These trends highlight the importance of understanding consumer demands and market opportunities in the evolving landscape of PCB manufacturing and assembly.