Unleashing the Power of Chinese Manufacturing in the Best PCB Production

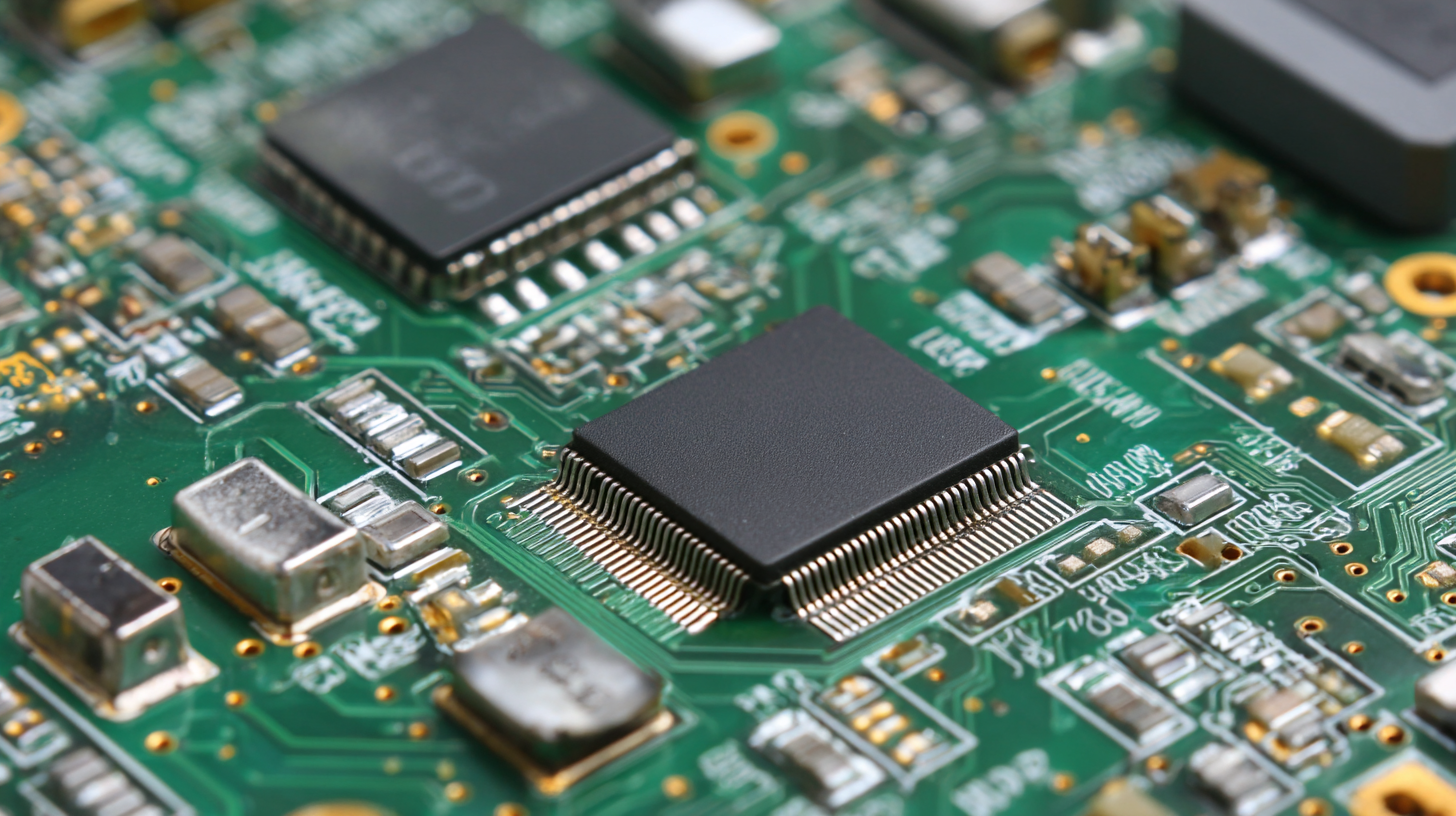

In today's rapidly evolving technological landscape, the demand for high-quality printed circuit boards (PCBs) has soared, positioning Chinese manufacturing at the forefront of this industry. The prowess of PCB manufacturing in China stems from its innovative techniques, scalability, and cost-effectiveness, making it a go-to choice for businesses worldwide seeking reliable and efficient production solutions.

However, with numerous manufacturers available, selecting the right partner can be a daunting task. Understanding the key factors that contribute to excellence in PCB manufacturing is essential for businesses aiming to optimize their products while minimizing risks. In this blog, we will explore how to effectively choose a quality manufacturer in the world of PCB production, ensuring that your electronic endeavors are supported by the best in the business.

The Rise of PCB Manufacturing in China: Statistics and Trends

The global landscape of PCB manufacturing is undeniably shifting, with China emerging as a critical player. Recent statistics show that China's PCB production has seen remarkable growth, outpacing many other regions. In just a few years, the country has established itself as the world's largest producer of printed circuit boards, meeting the booming demand in various industries such as consumer electronics, automotive, and telecommunications. This surge can be attributed to the country's investment in advanced manufacturing technologies and a skilled workforce, positioning it as a go-to destination for quality and efficiency.

Tips for businesses looking to leverage Chinese PCB manufacturing include establishing strong relationships with local suppliers and understanding the intricacies of Chinese regulations. Collaborating with manufacturers that have a proven track record in quality assurance can enhance product reliability. Additionally, staying informed about the latest trends in manufacturing technologies, such as automation and smart manufacturing, can give companies a competitive edge.

Another key point to consider is the importance of sustainability in the manufacturing process. As environmental regulations tighten globally, choosing manufacturers that prioritize eco-friendly practices can not only enhance brand reputation but also meet the evolving expectations of consumers. Embracing these strategies will not only maximize operational efficiency but also drive long-term growth in the dynamic PCB landscape.

Key Advantages of Chinese Manufacturing in PCB Production

Chinese manufacturing has established itself as a powerhouse in PCB (Printed Circuit Board) production, offering several key advantages that set it apart in the global market. One of the most significant benefits is cost efficiency. China’s extensive manufacturing ecosystem benefits from economies of scale, which allows for lower production costs compared to many other countries. This financial advantage makes it easy for companies to scale their operations and invest in innovation without the prohibitive overhead that can come with PCB manufacturing elsewhere.

Moreover, Chinese manufacturers excel in technological advancements and infrastructure. The country boasts a robust supply chain and a wealth of skilled labor, which enables quick turnarounds and high-quality production. With continuous investments in modernization and research, Chinese factories are equipped with the latest technologies and equipment to produce PCBs that meet the stringent standards of various industries. This capability ensures that clients receive products that are not only cost-effective but also cutting-edge, supporting the growing demand for advanced electronics in the global marketplace.

Understanding the Role of Automation in PCB Manufacturing Efficiency

The integration of automation in PCB manufacturing is revolutionizing the industry, leading to enhanced efficiency and production capabilities. According to a recent report by IPC, the global PCB market was valued at approximately $60 billion in 2021, with a projected growth rate of 5.2% annually. Automation technologies, including robotic assembly and automated inspection systems, are critical in meeting this rising demand while maintaining strict quality standards. Companies employing advanced automation can increase their production rates by up to 25%, helping them stay competitive in a rapidly evolving market.

Furthermore, automation not only boosts speed but also reduces human error, significantly improving the overall quality of PCBs. A report by Technavio highlights that automated processes can lower defect rates by as much as 30%. This shift towards automation is not merely a trend; it’s essential for manufacturers aiming to enhance operational efficiency. As the industry increasingly adopts smart manufacturing strategies, the synergy between automation and PCB production will undoubtedly lead to innovative solutions and sustainable growth, positioning Chinese manufacturers at the forefront of the global electronics landscape.

Understanding the Role of Automation in PCB Manufacturing Efficiency

Quality Control Standards: Ensuring Excellence in Chinese PCB Production

In the realm of PCB production, quality control standards are paramount for ensuring that products meet both domestic and international requirements. Chinese manufacturers have made significant strides in implementing rigorous quality management systems that align with global standards such as ISO 9001 and IPC-6012. These frameworks emphasize continuous improvement, process optimization, and defect prevention, which are essential in delivering high-quality printed circuit boards that stand the test of time.

Moreover, advanced technologies such as automated inspection and real-time monitoring are increasingly integrated into the manufacturing processes. These innovations not only enhance accuracy and efficiency but also minimize human error, ensuring that every PCB produced adheres to the highest quality benchmarks. By leveraging these quality control measures, Chinese PCB manufacturers can strengthen their competitive edge in the global market, providing clients with reliable products that fulfill a myriad of applications across various industries.

Unleashing the Power of Chinese Manufacturing in the Best PCB Production - Quality Control Standards: Ensuring Excellence in Chinese PCB Production

| Quality Control Dimension | Description | Measurement Method | Industry Standard | Current Compliance Rate |

|---|---|---|---|---|

| Materials Inspection | Verifying raw materials for quality | Visual and CT scanning | IPC-6012 | 95% |

| Soldering Quality | Evaluation of solder joint integrity | X-ray inspection | J-STD-001 | 90% |

| Functional Testing | Testing to ensure design functionality | Automated test equipment | IPC-2221 | 92% |

| Environmental Testing | Resistance to environmental conditions | Temperature and humidity testing | MIL-STD-883 | 88% |

| Dimensional Accuracy | Measurement of PCB dimensions | CMM and optical measuring | IPC-A-600 | 93% |

Future Innovations in PCB Manufacturing: What the Data Indicates

As the landscape of PCB manufacturing evolves, insights into future innovations reveal a burgeoning need for enhanced production techniques and efficiencies. Data indicates that the demand for AI-ready data center capacities is expected to rise significantly, with projections showing a growth rate of 33% annually until 2030. This surge is not only a testimony to the increasing reliance on advanced technologies but also presents a pivotal opportunity for manufacturers to adapt and scale operations accordingly.

The integration of AI and smart manufacturing technologies within the PCB sector could facilitate quicker production times and improved product quality, thereby addressing the evolving needs of global markets.

The integration of AI and smart manufacturing technologies within the PCB sector could facilitate quicker production times and improved product quality, thereby addressing the evolving needs of global markets.

Meanwhile, geopolitical shifts and evolving trade dynamics are reshaping supply chains worldwide. China’s advancement as a leader in innovative manufacturing reflects a broader trend where nations are focusing more on resilience and efficiency in their supply chains. As countries like the United States catalyze investments in clean energy and semiconductor manufacturing, the collaboration and competition between major economies highlight the critical importance of adaptable manufacturing strategies. Embracing these trends will be essential for PCB manufacturers aiming to stay relevant and competitive in the rapidly changing global economy.