Why PCB Assembly is Critical for Your Electronics Manufacturing Success

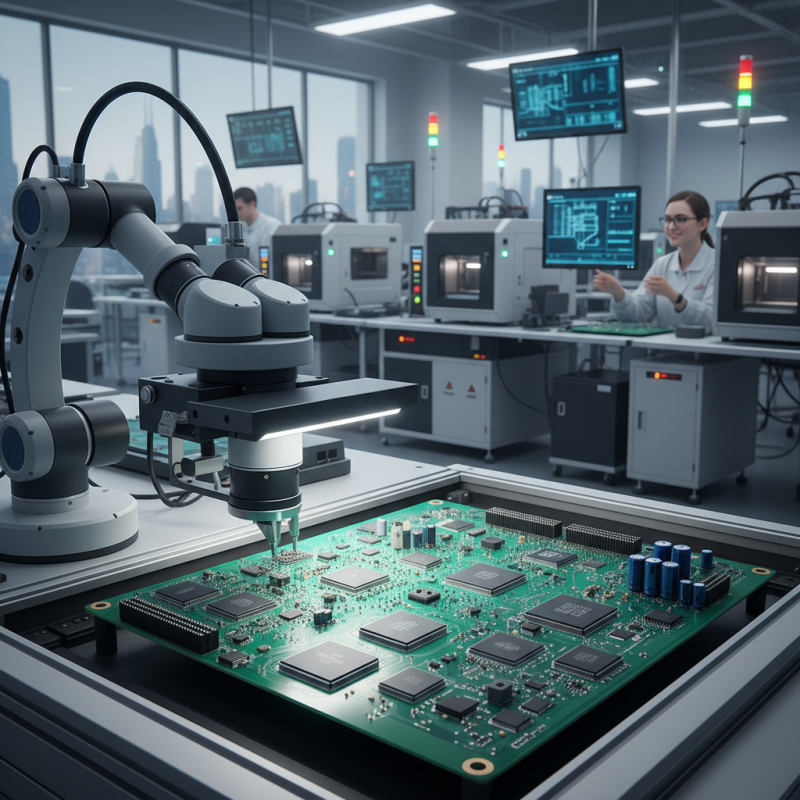

In the rapidly evolving landscape of electronics manufacturing, PCB assembly stands out as a fundamental pillar that can determine the success or failure of product development. According to industry expert Dr. Emily Zhang, a leading authority in electronic engineering, “Effective PCB assembly is not just a process; it is the backbone that ensures reliability and performance in modern electronics.” This encapsulates the vital role that PCB assembly plays in translating innovative designs into functional products.

As the demand for increasingly complex and compact electronic devices grows, the intricacies of PCB assembly have become paramount. It involves not only the physical integration of components onto the board but also requires precision in design and quality control to mitigate potential issues down the line. An efficient PCB assembly process directly correlates with reduced production costs and improved time-to-market, making it an essential focus for manufacturers striving to maintain competitiveness in the market.

With the stakes higher than ever, investing in advanced PCB assembly techniques and technologies can set leading companies apart in their pursuit of excellence. This emphasis on quality and innovation in PCB assembly practices is what ultimately drives the success of electronics manufacturing in today's fast-paced environment.

Importance of PCB Assembly in Electronics Manufacturing

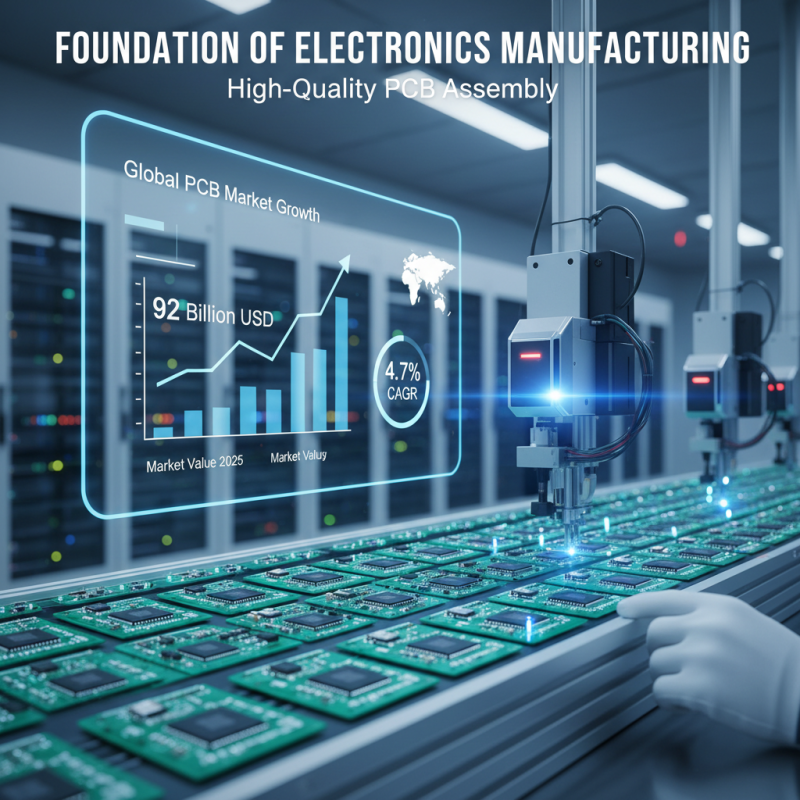

PCB assembly plays a pivotal role in the success of electronics manufacturing, serving as the foundation for the functionality and reliability of electronic devices. According to a report by Market Research Future, the global PCB assembly market is expected to reach $92 billion by 2025, with a compound annual growth rate (CAGR) of 4.7%. This growth underscores the increasing demand for efficient and effective assembly processes in the competitive landscape of electronics production. High-quality PCB assembly directly impacts product performance, making it essential for manufacturers striving to meet consumer expectations for durability and efficiency.

Moreover, the complexity of modern electronics requires precision in PCB assembly. With more than 50 billion connected devices anticipated by 2030, as reported by the International Data Corporation (IDC), the significance of flawless assembly processes becomes even more pronounced. Advances in technology demand an integration of miniaturization, enhanced thermal management, and effective component placement, all of which depend heavily on expert PCB assembly. Inadequate assembly techniques can lead to increased failure rates, resulting in costly recalls and diminished brand trust, emphasizing the necessity of investing in robust PCB assembly capabilities for manufacturing success.

Key Components of PCB Assembly Process

The PCB assembly process is pivotal in the electronics manufacturing industry, serving as the backbone for delivering quality products. Key components of this process include design verification, component placement, soldering, and inspection. Each segment requires precision to ensure that the final product meets the desired specifications and standards.

Off-line PCB laser depaneling systems are becoming increasingly significant in this realm. The market for these systems is projected to grow from $141.41 million in 2024 to $203.26 million by 2032, reflecting a compound annual growth rate of 4.7%. This trend highlights the industry's shift towards more efficient and effective manufacturing practices, where such systems enhance precision and reduce production time.

**Tips:** When designing your PCB, always prioritize the layout for manufacturability. Ensuring that components are easily accessible during the assembly process can reduce errors. Additionally, implementing robust inspection mechanisms at each stage of assembly is crucial for maintaining high-quality standards and minimizing defects, ultimately contributing to your product's success in the competitive electronics market.

Challenges in PCB Assembly and Solutions

PCB assembly is a vital process in electronics manufacturing, yet it comes with its own set of challenges. One of the primary difficulties is achieving precision in component placement. As modern electronic devices become increasingly compact and complex, even minor misalignments can lead to malfunctioning products. To combat this, manufacturers are investing in advanced automation technologies, such as pick-and-place machines that ensure high accuracy and speed in assembling PCBs.

Another significant challenge is managing thermal issues during the soldering process. Excessive heat can damage sensitive components, resulting in high failure rates. To address this, companies are adopting reflow soldering techniques that provide better temperature control. Additionally, implementing thermal simulation tools during the design phase can preemptively identify potential overheating problems. By proactively tackling these challenges, electronics manufacturers can enhance production efficiency and ensure the reliability of their products.

Impact of PCB Quality on Overall Product Performance

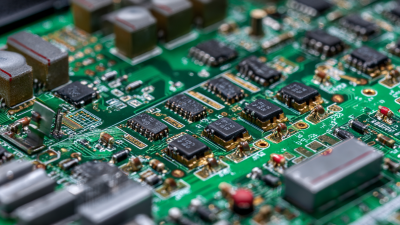

The quality of printed circuit boards (PCBs) plays a vital role in determining the overall performance of electronic products. When manufacturers prioritize high-quality PCB assembly, they ensure that each component functions optimally within the circuit. Poorly constructed PCBs can lead to issues such as signal interference, power loss, and increased susceptibility to damage. This not only affects the immediate functionality of the product but can also lead to long-term reliability concerns, ultimately impacting customer satisfaction and brand reputation.

Moreover, the intricacies of modern electronics, which often involve intricate designs and miniaturized components, necessitate an unwavering focus on PCB quality. Advanced manufacturing techniques and stringent quality control measures can significantly enhance the durability and efficiency of PCBs, reducing the likelihood of failure in various operating environments. As industries strive for innovation and competitiveness, investing in superior PCB assembly becomes a critical step in ensuring that electronic devices not only meet but exceed performance expectations.

Why PCB Assembly is Critical for Your Electronics Manufacturing Success - Impact of PCB Quality on Overall Product Performance

| Quality Dimension | Impact on Performance | Potential Issues | Improvement Strategies |

|---|---|---|---|

| Component Placement Accuracy | Ensures proper functionality and reduces defects | Short circuits, poor performance | Use advanced pick-and-place technology |

| Solder Quality | Critical for electrical connectivity | Cold joints, oxidation | Optimize soldering processes and materials |

| PCB Material Quality | Affects durability and thermal performance | Delamination, thermal damage | Select high-quality materials |

| Testing Procedures | Identifies defects before production scale | Undetected failures, warranty claims | Implement thorough testing protocols |

| Design for Manufacturability (DFM) | Enhances ease of assembly and lowers costs | Complex designs increase errors | Adopt DFM principles in design phase |

Future Trends in PCB Assembly for Electronics Industry

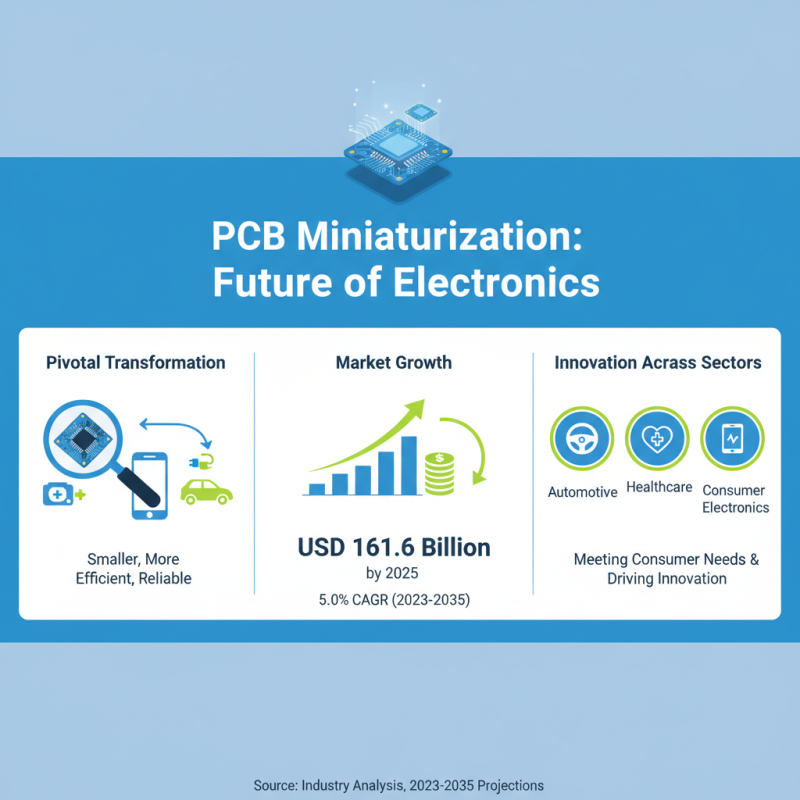

The electronics industry is experiencing a pivotal transformation marked by the miniaturization of printed circuit boards (PCBs), which is enhancing efficiency and reliability across various sectors. As the demand for compact and advanced electronic devices grows, the PCB assembly market is projected to reach USD 161.6 billion by 2035, with a compound annual growth rate (CAGR) of 5.0% during this period. This evolution not only meets consumer needs for smaller devices but also drives innovation in sectors such as automotive, healthcare, and consumer electronics.

In line with these trends, NEPCON ASIA 2025 will serve as a key platform for showcasing advancements in smart electronics manufacturing. Participants will include over 3,500 companies, emphasizing the critical nature of PCB assembly in modern electronic applications. As manufacturers embrace flexible and multilayer PCBs, these developments signal a broader shift in production capabilities, allowing for more intricate designs and improved functionality.

**Tip:** To stay competitive in this rapidly evolving market, businesses should focus on investing in advanced PCB assembly technologies and fostering partnerships with innovative suppliers. This proactive approach will not only enhance product offerings but also streamline manufacturing processes, ultimately contributing to long-term success and sustainability in the electronics landscape.

Related Posts

-

Understanding Product Features and Applications in Best PCB Manufacturing and Assembly

-

Innovative Examples of Printed Circuit Assembly that Set the Industry Standard

-

Navigating Import Export Certifications for Best Electronic Board Assembly Suppliers

-

Essential Tips for Identifying Top-Quality PCB Assembly Manufacturers

-

Innovative Examples of the Best Printed Circuit Board Designs in Today’s Technology

-

5 Best Strategies for Optimizing PCB Manufacturing Assembly Efficiency