Innovative Examples of Printed Circuit Assembly that Set the Industry Standard

In the rapidly evolving landscape of electronics manufacturing, printed circuit assembly (PCA) stands out as a cornerstone of innovation and efficiency. According to a recent report by the IPC (Institute for Printed Circuits), the global printed circuit board (PCB) market is projected to reach $87 billion by 2025, underscoring the critical role PCA plays in modern electronic devices. This surge is driven not only by the increasing demand for advanced consumer electronics but also by stricter manufacturing standards and emerging technologies such as IoT and 5G. Innovative PCA practices, including the integration of smart manufacturing processes and sustainable materials, are setting new industry standards that enhance performance and reliability. As companies strive to differentiate themselves in a competitive market, examining these exemplary PCA applications will reveal invaluable insights into the future of electronic assembly.

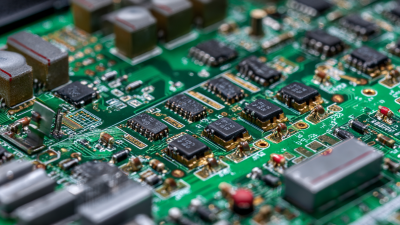

Examples of Cutting-Edge PCB Assembly Techniques Driving Industry Innovation

Printed Circuit Board (PCB) assembly is continually evolving, with cutting-edge techniques reshaping the industry landscape. One prominent innovation is the adoption of automated optical inspection (AOI) systems, which have improved defect detection rates by up to 90%, as reported by industry analysts. This advancement not only enhances quality control but also significantly reduces the time required for manual inspections, allowing manufacturers to scale production without compromising on reliability.

Additionally, the integration of surface mount technology (SMT) has led to a remarkable increase in assembly efficiency. According to a recent study by IPC, SMT can achieve component placement speeds exceeding 60,000 components per hour. This capability is critical in an era where the demand for compact and complex electronics is skyrocketing.

Furthermore, the development of flexible and hybrid PCBs is setting a new standard in design versatility, enabling applications in sectors ranging from wearable technology to automotive systems, thus driving innovation across multiple domains. The industry's commitment to these advanced PCB assembly techniques not only enhances performance but also positions companies at the forefront of electronic manufacturing advancements.

The Role of Automation in Transforming Printed Circuit Assembly Processes

The role of automation in transforming printed circuit assembly (PCA) processes cannot be overstated. Recent reports highlight that automation is set to enhance efficiency in PCA by up to 50%, reducing human error while maintaining high-quality standards. Automated systems, such as robotic soldering and vision inspection technologies, allow for precise placements and faster production cycles, consequently lowering overall production costs. A study by IPC – Association Connecting Electronics Industries reveals that companies implementing automation see significant improvements in throughput, with some reporting as much as a 30% increase in output.

Moreover, the integration of Industry 4.0 technologies, such as IoT and AI, is revolutionizing PCA by enabling real-time data analytics and predictive maintenance. According to a MarketsandMarkets report, the PCA automation market is projected to reach $15.2 billion by 2025, with key drivers being the growing demand for miniaturized electronic components and the need for efficient manufacturing processes. As companies continue to invest in these smart automation solutions, the landscape of printed circuit assembly is transforming, setting new industry standards and pushing the boundaries of innovation.

Sustainability Practices in PCB Assembly: Setting New Environmental Standards

Sustainability has become a focal point in the printed circuit board (PCB) assembly industry, prompting innovative practices that not only enhance productivity but also address environmental concerns. According to a recent report by IPC, about 75% of electronic manufacturing companies are now prioritizing eco-friendly materials and processes. This shift is largely driven by consumer demand for sustainable products, pushing manufacturers to adopt practices that reduce waste and minimize carbon footprints.

One of the most notable advancements in PCB assembly is the use of lead-free soldering techniques, which have been found to reduce toxic waste significantly. The Global E-Waste Monitor 2020 reported that over 53 million metric tons of electronic waste are generated annually, highlighting the urgent need for effective recycling programs. Many companies are now investing in closed-loop systems that recycle outdated circuit boards, recovering precious metals and other materials. By integrating such practices, the industry is not only complying with tighter environmental regulations but also setting an example of responsible manufacturing that aligns with today’s sustainability goals.

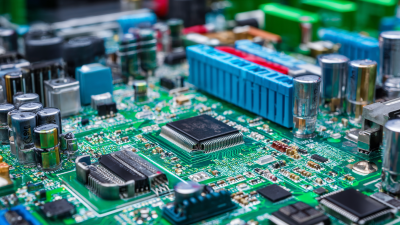

Leveraging Advanced Materials for Enhanced PCB Performance and Longevity

The evolution of printed circuit boards (PCBs) has dramatically transformed with the introduction of advanced materials that significantly enhance performance and longevity. These materials, such as polyimide, are designed to withstand extreme temperatures and mechanical stresses, making them ideal for high-performance applications. By integrating these materials into printed circuit assemblies, manufacturers can create more reliable and durable products that meet the rigorous demands of modern electronics, from consumer gadgets to aerospace components.

Moreover, the use of advanced materials allows for innovative design solutions that push the limits of traditional PCB technology. For example, metal-core PCBs incorporate thermal management properties that mitigate heat dissipation issues, crucial for LEDs and power electronics. These innovations not only improve the functionality of the assemblies but also prolong their lifespan, reducing the frequency of replacements and repairs. As the industry continues to embrace these cutting-edge materials, we can expect to see even more sophisticated and efficient circuit assemblies leading the way in technological advancement.

Innovative Examples of Printed Circuit Assembly that Set the Industry Standard

| Application | Advanced Material | Benefits | Performance Metrics | Longevity |

|---|---|---|---|---|

| Consumer Electronics | Thermal Interface Materials | Improved heat dissipation | Temperature resistance up to 150°C | Over 10 years |

| Automotive | High-Temperature Laminates | Enhanced durability | Vibration resistance tested up to 20g | 15-20 years |

| Medical Devices | Polyimide Films | Flexibility and biocompatibility | Flexible with mechanical strength over 200MPa | Lifetime of over 20 years |

| Telecommunications | Low Loss Dielectrics | Improved signal integrity | Dissipation factor of <0.02 | 30+ years |

| Aerospace | Metal Core PCBs | Superior thermal conduction | Thermal conductivity >170 W/mK | 25 years |

Case Studies: Companies Leading the Way in Innovative PCB Assembly Solutions

Leading companies in the PCB assembly sector are harnessing innovative technologies to redefine industry standards. A recent report highlights that manufacturers are focusing on targeted investments in digital and data solutions to enhance efficiency and innovation, particularly in response to ongoing skill gaps. For instance, the Electronic Manufacturing Services outlook for 2025 indicates that advancements in areas such as artificial intelligence and the Internet of Things are driving significant transformations in manufacturing processes. These changes enable organizations to streamline workflows and improve production precision, which is critical in meeting the growing demands for high-quality electronic components.

Moreover, as the industry embraces miniaturization and advanced materials, case studies reveal how several firms are integrating hybrid renewable energy solutions into their operations. By combining solar and wind technologies, these companies are not only addressing energy challenges but also improving sustainability in their PCB assembly processes. Such initiatives position them as leaders in the field, setting benchmarks for other organizations while aligning with broader environmental goals. As the landscape evolves, continuous adaptations and innovations in PCB assembly practices will be crucial for maintaining competitiveness and driving industry growth.

Related Posts

-

Understanding Product Features and Applications in Best PCB Manufacturing and Assembly

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

Navigating Import Export Certifications for Best Electronic Board Assembly Suppliers

-

Essential Tips for Identifying Top-Quality PCB Assembly Manufacturers

-

Innovative Examples of the Best Printed Circuit Board Designs in Today’s Technology

-

Unleashing the Power of Chinese Manufacturing in the Best PCB Production