Understanding the Future of Printed Circuit Board Innovations in Technology

The landscape of printed circuit board (PCB) technology is undergoing a significant transformation, driven by innovations that cater to the demands of modern electronic devices. According to a report by MarketsandMarkets, the global PCB market is expected to reach USD 78.8 billion by 2025, growing at a CAGR of 4.1% from 2020 to 2025, reflecting a rising trend in miniaturization and complexity of electronic products. This growth presents both challenges and opportunities for manufacturers and designers, necessitating a deep understanding of emerging technologies such as flex-PCBs, HDI, and embedded components.

To stay competitive, stakeholders in the PCB industry must adapt to advancements in materials and manufacturing techniques while also addressing the critical issues of sustainability and supply chain resilience. This article aims to explore various how to strategies for leveraging the latest innovations in PCB technology to foster future growth and efficiency in electronic applications.

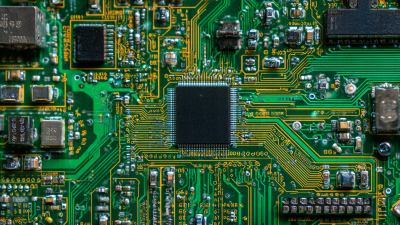

Exploring Emerging Technologies in Printed Circuit Board Manufacturing

The landscape of printed circuit board (PCB) manufacturing is on the brink of transformation, thanks to a surge in emerging technologies. Additive manufacturing, also known as 3D printing, is revolutionizing traditional PCB fabrication processes. This technology allows for the rapid prototyping of complex designs, reducing material waste and lead times associated with conventional methods. Moreover, by enabling the creation of intricate geometries that would be impossible to achieve with traditional techniques, additive manufacturing opens up new possibilities for innovation in electronic device design.

Another significant advancement in PCB technology is the integration of advanced materials. With the rise of flexible and stretchable electronics, manufacturers are exploring the potential of new substrates, such as organic materials and nanomaterials. These innovations not only enhance the performance and functionality of PCBs but also enable the development of lighter, thinner, and more versatile electronic devices. Additionally, the incorporation of smart materials capable of self-healing and reactive functionalities presents exciting opportunities for future applications in wearable technology and IoT devices. As these technologies continue to evolve, they promise to reshape the industry and drive the next generation of electronic devices.

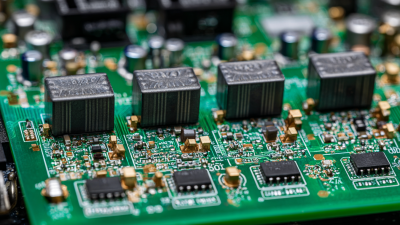

Harnessing Advanced Materials for Enhanced PCB Performance

The future of printed circuit boards (PCBs) hinges on the development and application of advanced materials that enhance performance, reliability, and miniaturization. According to a recent report by Market Research Future, the global PCB market is expected to grow at a CAGR of 4.1% from 2021 to 2027, driven by the rising demand for more efficient and compact electronic devices. Advanced materials such as high-frequency laminates and flexible substrates are becoming increasingly vital, enabling designs that support high-speed data transmission and reduced signal loss.

Incorporating materials like polymers and composites not only boosts thermal performance but also enhances electrical properties critical for next-generation applications. For example, the increasing use of High-Density Interconnect (HDI) technology requires precise material specifications to accommodate the complex routing of densely packed components. The IPC (Institute for Printed Circuits) emphasizes that the right material choice can extend the lifespan of PCBs, reducing maintenance costs and improving overall device reliability.

The integration of these advanced materials is essential for driving innovations in smartphones, automotive electronics, and IoT devices, setting the stage for a more efficient and sustainable electronics ecosystem.

Implementing Automation and AI to Revolutionize PCB Production

The future of printed circuit board (PCB) manufacturing is being significantly shaped by the integration of automation and artificial intelligence (AI) technologies. According to a report from Research and Markets, the PCB market is projected to reach $100 billion by 2025, driven largely by innovations in production methods. Automation enhances production efficiency by minimizing human error and increasing throughput. It is not uncommon for modern PCB manufacturing facilities to achieve a 30% reduction in labor costs through automation, allowing for faster turnaround and increased competitiveness in the market.

Furthermore, the implementation of AI in the production process allows manufacturers to harness data analytics for improved decision-making. By utilizing machine learning algorithms, companies can predict equipment failures before they occur, as highlighted in a study by McKinsey, which states that predictive maintenance can reduce unplanned downtime by up to 50%. AI also facilitates real-time quality control, enabling manufacturers to detect defects early in the production cycle, thereby significantly improving yield and reducing waste. This convergence of automation and AI is set to not only enhance operational efficiency but also inspire new designs and functionalities in PCB technology, paving the way for a more innovative future.

Sustainable Practices in PCB Design and Fabrication

The future of printed circuit board (PCB) design and fabrication is increasingly intertwined with sustainable practices, reflecting the growing demand for environmentally responsible technologies. As the electronics industry expands, traditional PCB manufacturing methods often generate significant waste and use hazardous materials, leading to detrimental environmental impacts. To address these concerns, innovative techniques such as the use of biodegradable substrates and non-toxic inks are being developed, paving the way for greener alternatives.

Moreover, sustainable practices in PCB design involve the incorporation of modular designs that enhance recyclability. By embracing a circular economy model, manufacturers can optimize material usage while reducing the lifecycle impact of PCBs. Techniques such as advance computer-aided design (CAD) software enable designers to create more efficient layouts, minimizing material waste. Collaborations between industry stakeholders, along with advancements in manufacturing technologies, such as additive manufacturing, further support the transition toward eco-friendly PCB solutions, ensuring that future innovations align with sustainability goals.

Understanding the Future of Printed Circuit Board Innovations

This chart illustrates the projected advancements in sustainable practices in PCB design and fabrication over the next five years. The data reflects the increasing adoption of eco-friendly materials and processes, aiming to reduce the environmental impact of circuit board manufacturing.

Future Trends in PCB Miniaturization and Functional Integration

The future of printed circuit boards (PCBs) is increasingly oriented towards miniaturization and functional integration. As electronic devices become more compact and multifunctional, the demand for smaller, yet more powerful PCBs is on the rise. Innovations in materials and manufacturing processes facilitate the creation of thinner boards with higher component density, enabling the integration of complex circuits in a limited space. This trend not only enhances the performance of devices but also paves the way for new applications in wearables and Internet of Things (IoT) devices, where real estate is at a premium.

Another significant aspect of future PCB innovations is the advancement of functional integration. Engineers are now able to embed passive and active components directly onto the PCB, reducing the need for additional circuit elements and connections. This streamlined design leads to improved reliability and performance, while also simplifying the assembly process. Emerging technologies such as flexible and stretchable PCBs further support this trend, allowing for new form factors and innovative product designs. As industries continue to push the boundaries of what's possible, the evolution of PCB technology will be critical to realizing the next generation of electronic devices.

Related Posts

-

Common Issues Faced in High Density PCB Circuit Design

-

The Ultimate Guide to PCB Fabrication: Navigating the 2023 Industry Landscape and Beyond

-

Ultimate Checklist for Selecting the Best PCB Fabrication Services Worldwide

-

Exploring Innovations in Printed Circuit Board Technology at the 138th Canton Fair 2025

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

10 Essential PCB Printing Techniques You Need to Know