What is a Circuit Board and How Does It Work?

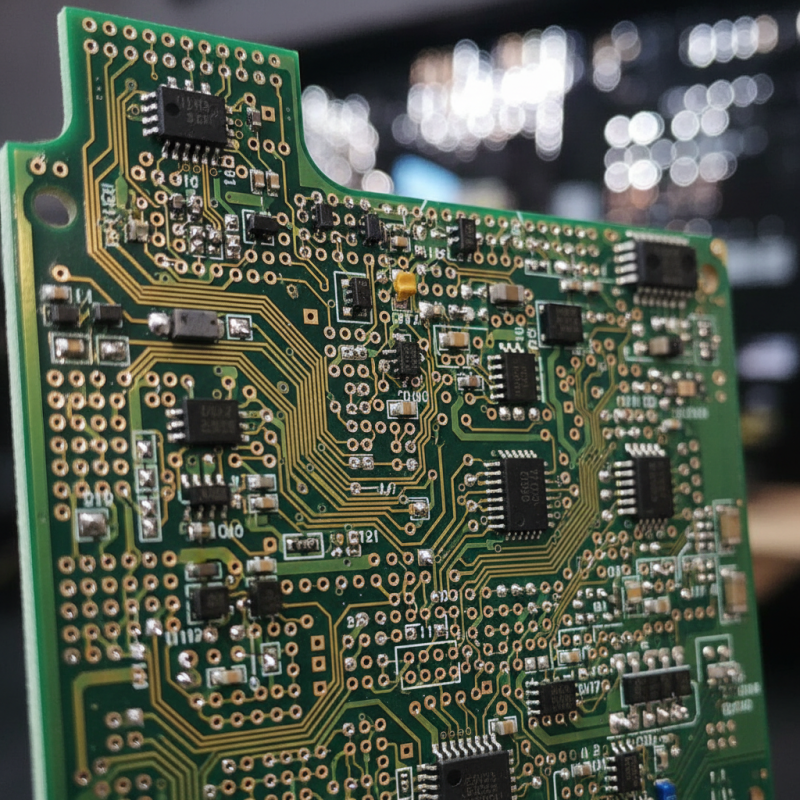

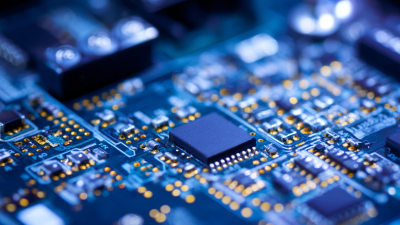

A circuit board is an essential component in modern electronics. It serves as a backbone, connecting various electronic parts to enable functionality. Without a circuit board, devices like smartphones, computers, and televisions would not operate as intended.

The design of circuit boards can seem complex. In reality, they are made up of simple materials, such as fiberglass and copper. These materials create pathways that electricity travels along. It is fascinating how something so small can impact our daily lives in significant ways.

However, understanding a circuit board isn’t always straightforward. Many people overlook its importance. Mistakes in its design can lead to device failures. Such oversights might start discussions on better practices. We must appreciate the craft of circuit board design for innovation. It brings both challenges and opportunities for improvement.

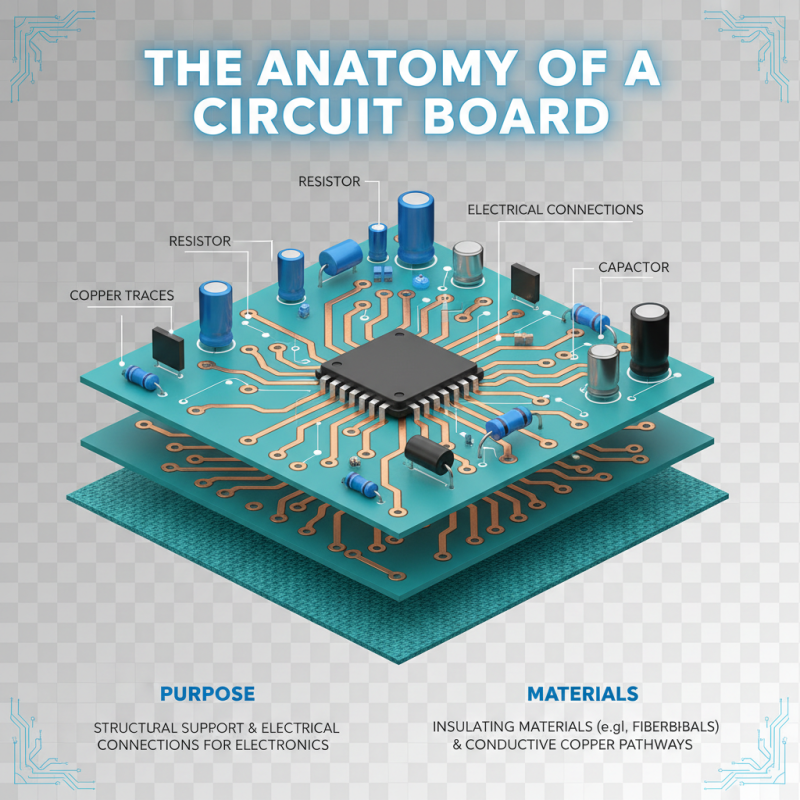

Definition and Purpose of a Circuit Board

A circuit board is a fundamental component in electronic devices. Its primary purpose is to provide structural support and electrical connections for various electronic components. Made of insulating materials, such as fiberglass, it features conductive pathways made from copper. These pathways connect components like resistors, capacitors, and microchips.

The design of a circuit board is crucial. It dictates how signals flow within a device. A well-designed board can enhance performance, but mistakes can lead to malfunctions. For example, if the pathways are too close, they may cause short circuits. These design challenges require careful planning and testing.

In addition, circuit boards can vary in complexity. Some are simple, with only a few components, while others are intricate, housing hundreds of parts. Manufacturers often face trade-offs in design. They must balance size, cost, and functionality. It's a delicate process that demands attention to detail and ongoing improvement.

Basic Components of Circuit Boards

Circuit boards are essential for connecting various electronic components. They provide a platform for devices to function. The layout and design of these boards determine their effectiveness.

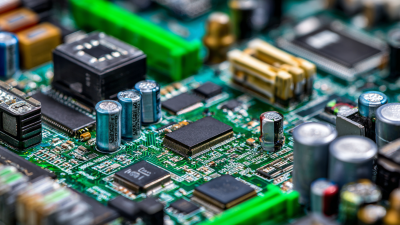

Basic components of circuit boards include resistors, capacitors, and integrated circuits. Resistors control the flow of electricity. They limit current and protect other components. Capacitors store and release energy. They ensure that voltage remains stable. Integrated circuits combine multiple functions in one small chip. These chips are vital for modern electronics, making devices smaller and faster.

Wiring is another crucial aspect. The pathways allow signals to travel quickly between components. However, improper connections can disrupt operations. Many beginners struggle with layout efficiency. The level of complexity in designing a circuit board can be overwhelming. Each decision can impact performance, making it essential to understand the basics fully. The world of circuit boards offers both challenge and opportunity.

How Circuit Boards Are Manufactured

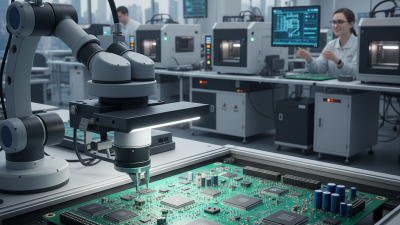

Manufacturing a circuit board is a complex process. It involves various steps that require precision and attention to detail. First, a substrate is chosen. This material provides the base for the entire board. Common materials include fiberglass and epoxy resin. The chosen substrate is then treated to enhance its electrical properties.

Next, designers create a layout using specialized software. This design includes the placement of components and pathways for electrical connections. Once the layout is finalized, the design is transferred to the substrate. This can be done using photolithography or other methods. Imperfections at this stage can lead to circuit failures later.

After the design is applied, the board undergoes a drilling process. Tiny holes are created for component leads. The holes need to be precisely positioned and sized. Any mistakes here could require a complete redo. Once drilled, the board is plated with copper to enable electrical connectivity. Each step must be carefully monitored. A small error can disrupt the entire manufacturing process, leading to costly delays and rework.

The Role of Circuit Boards in Electronics

Circuit boards are vital components in modern electronics. They serve as the backbone for electronic devices, providing a pathway for electrical signals. Without them, many of our everyday gadgets wouldn’t function. These boards typically consist of layered materials that hold circuits, which connect various components. Imagine a complex urban grid, with roads leading to houses, and each road represents a circuit.

The design of a circuit board is an intricate process. Engineers meticulously plan the layout to ensure optimal performance. They consider the placement of components like resistors, capacitors, and microchips. Misplacing a single component can lead to failure, making precision crucial. There’s no room for error in this world. Reflecting on the process, one might ask if the designs are truly efficient. Can they be improved?

The role of circuit boards extends beyond mere connections. They also protect components from environmental factors. Some boards are coated for durability, resisting moisture and dust. This protection is essential for devices used in harsh conditions. However, the materials used can sometimes be problematic. Are they environmentally friendly? Such concerns often arise, urging engineers to seek sustainable alternatives.

Common Applications of Circuit Boards

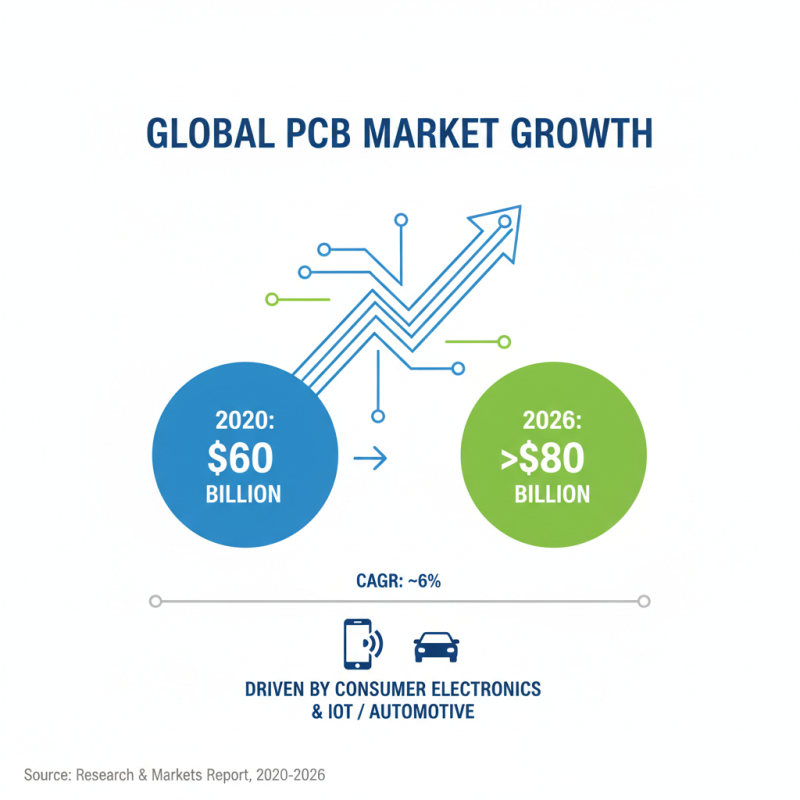

Circuit boards are vital in modern electronics, serving various applications across numerous industries. They are found in smartphones, computers, and automotive systems. According to a report by Research and Markets, the global PCB market size was valued at approximately $60 billion in 2020 and is expected to reach over $80 billion by 2026. This growth is driven by the increasing demand for consumer electronics and IoT devices.

In the automotive sector, circuit boards play a crucial role. They manage everything from navigation systems to advanced driver-assistance systems (ADAS). Reports indicate that the automotive PCB market alone could reach $20 billion by 2025, fueled by the rise of electric and autonomous vehicles. However, the reliance on these complex boards creates challenges. Just a single design error can lead to significant costs and delays.

Healthcare applications are also significant. Circuit boards in medical devices ensure accurate monitoring and diagnostics. The medical PCB market is expected to grow as telemedicine rises. Yet, as technology advances, the risk of failure rises too. The stakes are high, as safety is paramount in health-related devices. Each circuit board faces scrutiny, reflecting the need for rigorous testing and quality assurance across applications.

Related Posts

-

Emerging Trends in Circuit Board Design for 2025: Innovating for the Future

-

Mastering Electronic Board Manufacturing Techniques A Comprehensive Tutorial for Industry Professionals

-

Essential Tips for Identifying Top-Quality PCB Assembly Manufacturers

-

Digital Success in Electronic Board Manufacturing Strategies for Global Buyers

-

Why PCB Assembly is Critical for Your Electronics Manufacturing Success

-

5 Best Strategies for Optimizing PCB Manufacturing Assembly Efficiency