How to Choose the Right Flexible Printed Circuit for Your Project

Choosing the right flexible printed circuit is crucial for the success of any electronic project. Flexible printed circuits (FPC) offer distinct advantages over traditional rigid circuits, such as lightweight design, compactness, and the ability to bend in various configurations. These features make them ideal for applications in a myriad of industries, from consumer electronics to medical devices. However, with a variety of options available in the market, selecting the ideal FPC requires careful consideration of multiple factors.

When embarking on this journey, it's essential to understand the specific requirements of your project. Factors such as dimensions, electrical performance, and durability play a significant role in determining the best flexible printed circuit for your needs. Additionally, understanding the manufacturing processes and materials involved will help in making informed decisions, ensuring optimal performance and reliability. The following guide will delve into key aspects to consider when choosing a flexible printed circuit, helping you navigate the decision-making process to achieve the desired outcomes for your project.

Understanding Flexible Printed Circuits: Key Features and Benefits

Flexible printed circuits (FPCs) are a critical component in modern electronics, offering unique advantages that enhance design flexibility and application versatility. These circuits are engineered from flexible substrates and come with multiple layers of conductive pathways, enabling them to bend, twist, and fit into compact spaces that traditional rigid PCBs cannot accommodate. According to a recent market analysis by Research and Markets, the global flexible printed circuit industry is expected to reach $30 billion by 2027, fueled by the rising demand in sectors such as automotive, healthcare, and consumer electronics.

One of the key features of FPCs is their lightweight and compact design. This is particularly beneficial in applications that require miniaturization, such as wearable devices and smartphones. Moreover, FPCs possess excellent thermal management properties, which ensure that devices remain operational even under high temperatures. A study conducted by IDTechEx forecasts that the adoption of flexible circuits will increase significantly in the automotive industry, especially in electric vehicles, where effective heat dissipation is critical. The ability of FPCs to withstand repeated bending cycles without compromising performance further emphasizes their reliability and durability, making them an ideal choice for various challenging environments.

Identifying Project Requirements for Flexible Printed Circuit Selection

When selecting a flexible printed circuit (FPC) for your project, the first step is to identify and understand your specific project requirements. This involves assessing the intended application of the circuit, including the required electrical performance, flexibility, and durability. Consider factors such as the operating environment—will the FPC be subjected to extreme temperatures, humidity, or mechanical stress? Additionally, the complexity of the circuit design, the number of layers needed, and the footprint available in the assembly should also be taken into account. Each of these aspects significantly influences the type of materials and manufacturing processes that will be appropriate for your FPC.

Another critical element is the electrical characteristics that your project demands. Evaluate the required signal integrity, impedance control, and overall electrical performance. Make sure to consider the connection methods as well, such as pads or via placements, which can impact the circuit’s functionality and ease of assembly. Understanding these project requirements not only streamlines the selection process but also ensures that the final product will meet performance expectations and reliability standards for its intended application. This thorough preliminary analysis can save time and resources while also enhancing the overall success of your project.

Material Choices for Flexible Printed Circuits: What to Consider

When selecting materials for flexible printed circuits (FPCs), several critical factors should be considered to ensure the final product meets the demands of your project. The substrate material is one of the primary considerations; options such as polyimide and polyester are widely used due to their excellent flexibility and thermal stability. Polyimide, for instance, is known for its high-temperature resistance, making it suitable for applications that may experience extreme heat. Conversely, polyester is often chosen for cost-sensitive applications where extreme flexibility is not necessary.

Another essential aspect is the conductive material used in the circuit. Copper is the most common choice due to its excellent conductivity and reliability. However, in specific applications where weight is a concern, alternative materials such as aluminum or even printed conductive inks may be explored. Additionally, the thickness of the conductive layer plays a crucial role, as thicker layers provide greater durability, while thinner layers can offer more flexibility in design. Furthermore, consider the environment in which the FPC will operate, as factors such as humidity, temperature fluctuations, and exposure to chemicals can influence the longevity and performance of the chosen materials.

How to Choose the Right Flexible Printed Circuit for Your Project - Material Choices for Flexible Printed Circuits: What to Consider

| Material Type | Flexibility | Temperature Range (°C) | Cost (per sq. ft.) | Applications |

|---|---|---|---|---|

| Polyimide | High | -269 to 400 | $5.00 | Aerospace, Medical Devices |

| Polyester | Moderate | -40 to 150 | $3.00 | Consumer Electronics |

| Polyvinyl Fluoride (PVF) | High | -100 to 200 | $4.00 | Industrial Applications |

| LCP (Liquid Crystal Polymer) | Very High | -196 to 260 | $7.00 | High-Frequency Circuits |

| FR-4 | Low | -40 to 130 | $2.50 | General Purpose Circuits |

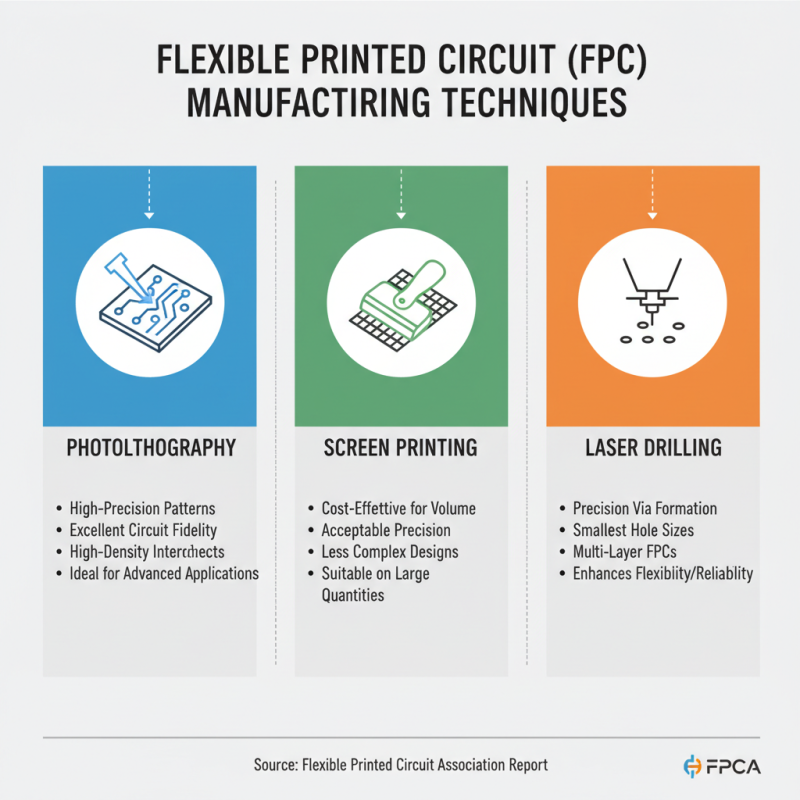

Evaluating Manufacturing Techniques for Flexible Printed Circuits

When evaluating manufacturing techniques for flexible printed circuits (FPCs), it's essential to understand the various processes that directly affect product performance and reliability. Key manufacturing methods include photolithography, screen printing, and laser drilling, each offering distinct advantages depending on the application's requirements. According to a report by the Flexible Printed Circuit Association, photolithography is commonly utilized for high-precision patterns and yields excellent circuit fidelity, making it ideal for high-density interconnects. Conversely, screen printing is often favored for its cost-effectiveness in producing larger quantities, while still maintaining an acceptable level of precision for less complex designs.

Additionally, recent advancements in manufacturing technology, such as additive manufacturing and improved materials, are diversifying the landscape of FPC production. A study from MarketsandMarkets indicates that the global flexible printed circuit market is projected to reach USD 58.1 billion by 2025, driven by innovation in materials and processes. The emergence of hybrid circuits, which combine flexible and rigid technologies, exemplifies the shifts in manufacturing techniques that cater to the evolving demands of industries like consumer electronics, automotive, and medical devices. As projects become more intricate, the ability to select the appropriate manufacturing technique can significantly influence not only functionality but also cost efficiency and time-to-market.

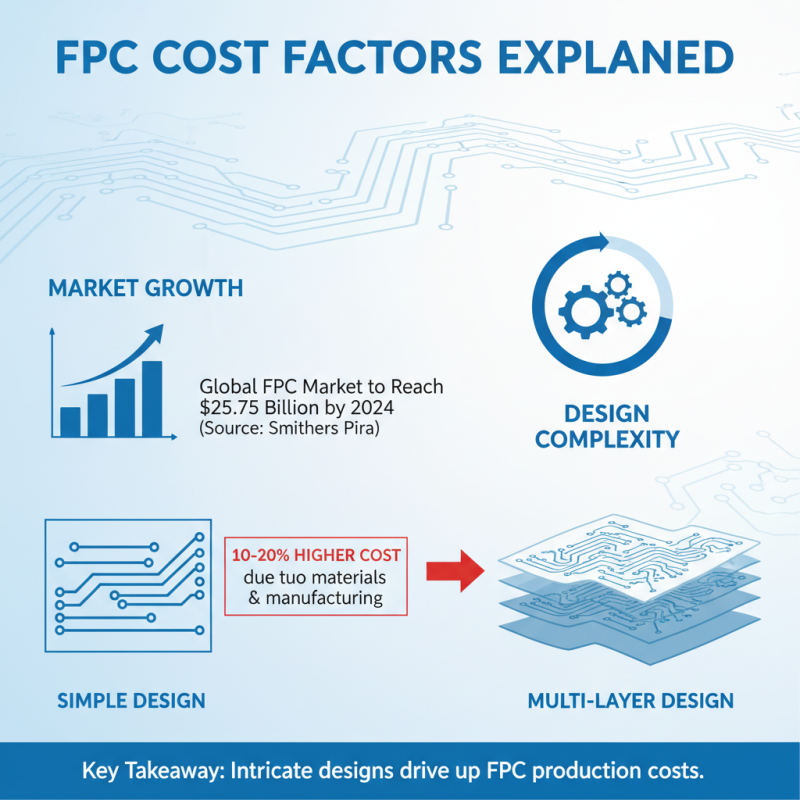

Assessing Cost Factors in Flexible Printed Circuit Design and Production

When selecting a flexible printed circuit (FPC) for your project, understanding the cost factors involved in its design and production is crucial. According to a report by Smithers Pira estimating the flexible electronics market, the global flexible printed circuit market is anticipated to reach $25.75 billion by 2024, highlighting the increasing demand for innovative circuit solutions. One significant cost factor is the complexity of the design itself. Intricate designs with multiple layers and fine traces can increase production costs dramatically. On average, the cost of fabricating a multi-layer FPC can be 10-20% higher than simpler designs, due to the added materials and manufacturing processes required.

Another important aspect to consider is the choice of materials. High-performance substrates and advanced conductive materials may result in enhanced functionality but can significantly impact the overall budget. For instance, polyimide substrates, which are known for their high thermal stability, can cost up to 50% more than standard polyester alternatives. Furthermore, according to a report by IDTechEx, approximately 30% of the total cost of FPCs is attributed to material selection. Thus, balancing performance requirements with cost constraints is essential for project viability. Effective budgeting must consider not only the upfront costs but also the long-term implications of design choices on manufacturing and assembly processes.

Related Posts

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

Innovative Examples of the Best Printed Circuit Board Designs in Today’s Technology

-

Understanding Product Features and Applications in Best PCB Manufacturing and Assembly

-

How to Choose the Best PCB Fabrication Partner for Global Supply Chain Success

-

Common Issues Faced in High Density PCB Circuit Design

-

Innovative Examples of Printed Circuit Assembly that Set the Industry Standard