How to Choose the Right Electronic Board for Your Project Needs

In today's rapidly evolving technological landscape, the selection of the right electronic board for your project is crucial to its success. With the global electronic board market projected to reach USD 100 billion by 2025, growth driven by advancements in IoT, automation, and consumer electronics, the stakes have never been higher. Choosing the appropriate electronic board not only influences the functionality and efficiency of your project but also its overall cost-effectiveness and time-to-market. According to a recent report by Research and Markets, about 70% of communications devices rely on custom electronic boards, highlighting their critical role in modern developments. This blog aims to guide you through the essential considerations and steps necessary to make an informed decision, ensuring that your project meets its objectives while leveraging the vast potential of electronic board technology.

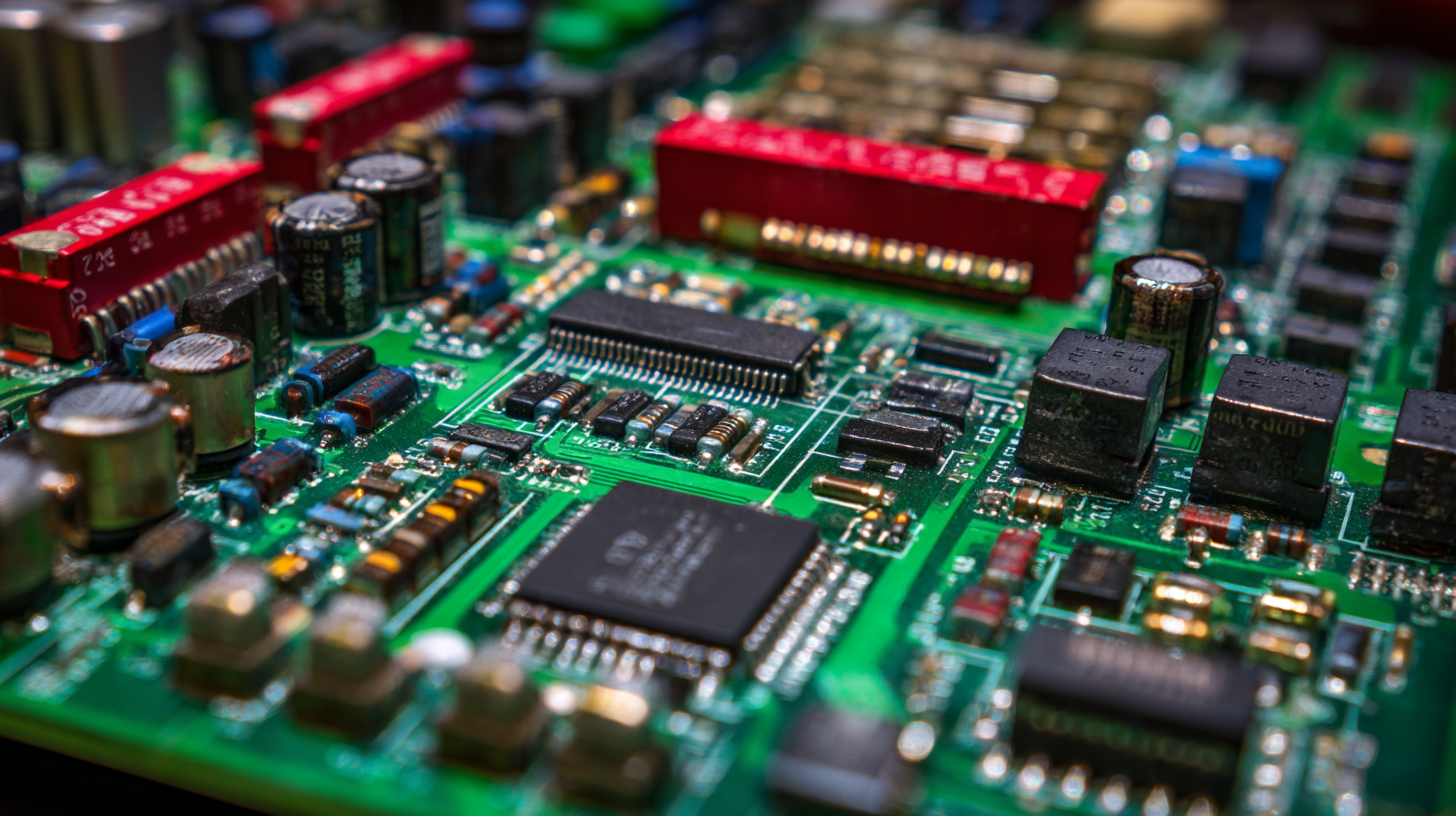

Understanding Different Types of Electronic Boards: A Comprehensive Overview

When embarking on an electronic project, understanding the various types of electronic boards available is crucial for making informed decisions. From microcontrollers like Arduino and Raspberry Pi to development boards such as ESP8266, each serves a unique purpose and caters to different project requirements. For instance, Arduino boards are excellent for beginners, providing a straightforward way to dive into coding and electronics, while Raspberry Pi offers a more powerful platform for complex applications requiring substantial processing power.

Tips for selection include assessing your project’s specifications and the technical skills at your disposal. If your project involves simple tasks like controlling sensors, a basic Arduino board would suffice. However, for projects that demand wireless communication or internet connectivity, consider boards like ESP32 or Raspberry Pi. Additionally, factor in the availability of community support and documentation, as robust resources can significantly expedite your learning curve and troubleshooting process.

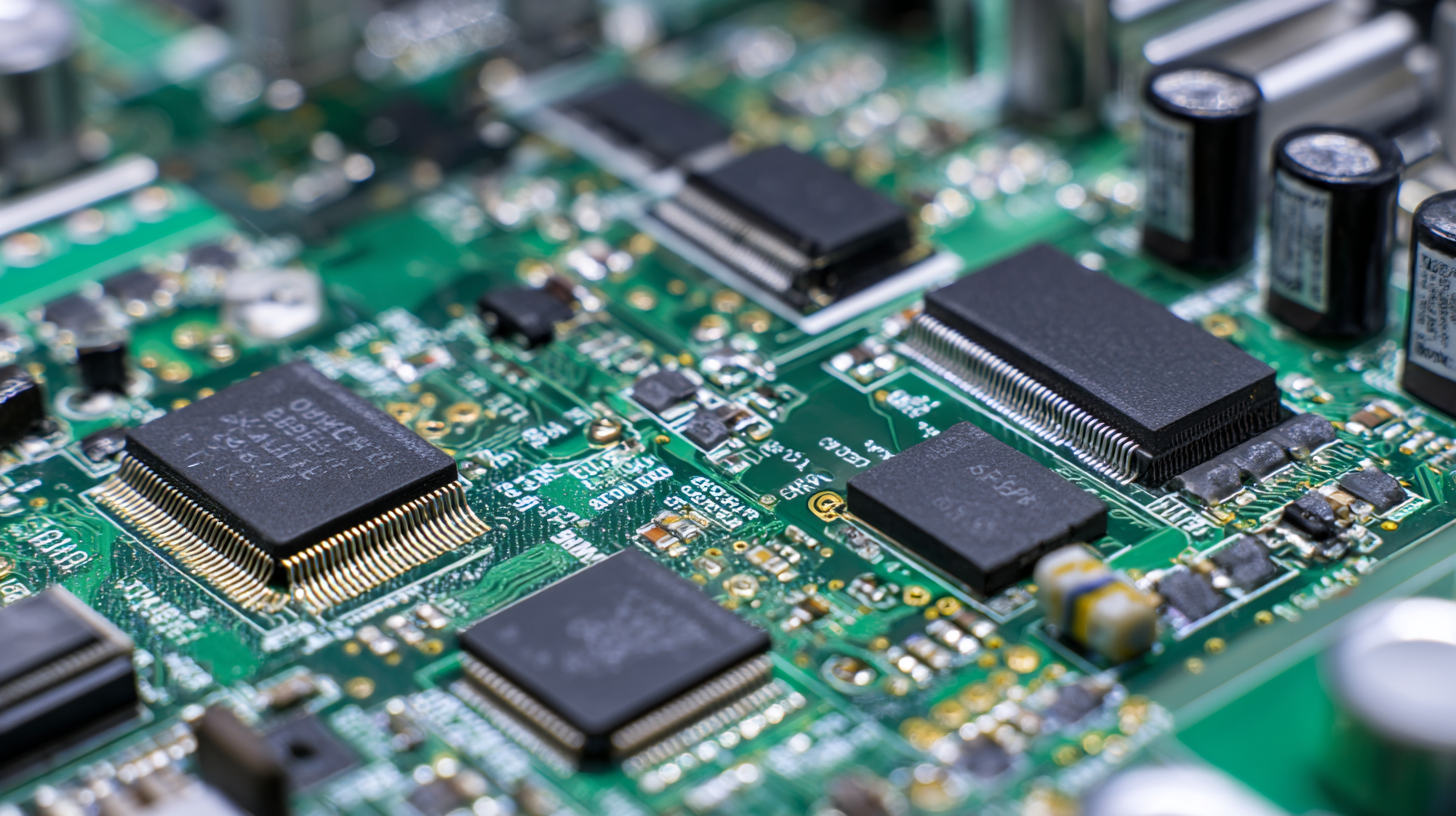

Key Specifications to Consider: Size, Processing Power, and Connectivity Options

When selecting the right electronic board for your project, understanding key specifications such as size, processing power, and connectivity options is crucial. The size of the board impacts both your project's physical design and its integration capabilities. Smaller boards like the Raspberry Pi Zero can fit into compact spaces for wearable technology or portable devices, while larger boards like the Arduino Mega offer more input and output ports for expansive projects requiring multiple sensors and actuators.

Processing power determines how efficiently your board can handle tasks. For applications that demand real-time processing, such as data streaming or complex calculations, boards equipped with powerful CPUs or GPUs, like the NVIDIA Jetson Nano, are ideal. In contrast, if your needs are basic, a simpler board like the Arduino Uno may suffice, providing sufficient processing capability for lower-demand applications.

Finally, connectivity options—including USB, Bluetooth, Wi-Fi, and Ethernet—play a significant role in how your project interacts with other devices and the internet. For IoT projects, a board with robust wireless connectivity options enables seamless communication with cloud platforms or other smart devices. Choose a board that aligns with your connectivity requirements to ensure a smooth and efficient workflow for your project.

Comparison of Key Specifications for Electronic Boards

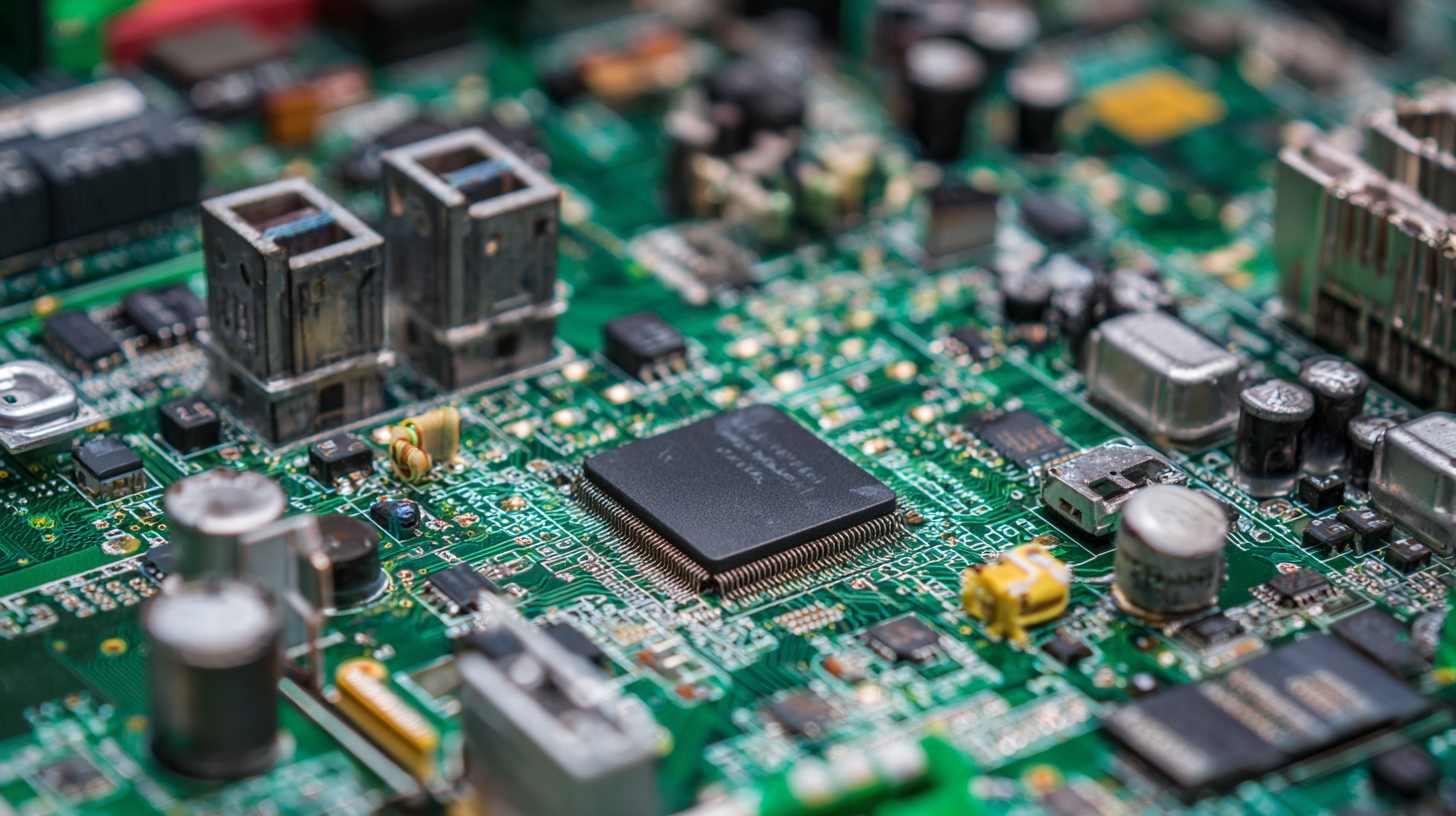

Assessing Your Project Requirements: Prototyping vs. Production Boards

When embarking on an electronics project, choosing between prototyping and production boards is crucial. Prototyping boards are designed for flexibility, allowing rapid testing and iteration. These boards often come with configurable connections and extensive support for various components, perfect for designers and engineers who are testing innovative concepts, like the recently evaluated Perf+ protoboard, which aims to offer a practical replacement for traditional perfboards. This adaptability is essential for projects, especially those in experimental phases, where changes are frequent and requirements are not yet set in stone.

In contrast, production boards are created for scalability and reliability, meant to be used in final products. As the manufacturing landscape evolves, with advancements in areas such as digital manufacturing and prototypes for innovative projects making strides in sectors like automotive and renewable energy, it’s essential to evaluate how your project fits within these developments. For instance, recent initiatives involving hydrogen fuel cell prototypes highlight the importance of robust production solutions that can withstand real-world applications. Ultimately, understanding whether your needs lean toward prototyping or production will help inform your decision and ensure the successful execution of your project.

How to Choose the Right Electronic Board for Your Project Needs - Assessing Your Project Requirements

| Criteria | Prototyping Boards | Production Boards |

|---|---|---|

| Cost | Low to Moderate | Moderate to High |

| Flexibility | High | Low |

| Development Time | Short | Long |

| Ease of Use | User-friendly | Requires expertise |

| Customization | High | Limited |

| Production Volume | Low | High |

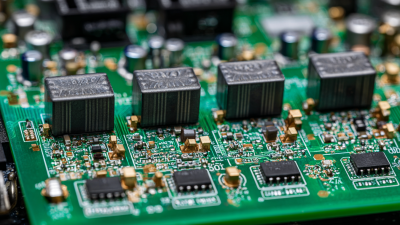

Evaluating Cost vs. Performance: Budgeting for Your Electronic Board Needs

When embarking on the journey of selecting the right electronic board for your project, evaluating the cost versus performance is crucial. According to a report by MarketsandMarkets, the global market for electronic circuit boards is projected to reach $80 billion by 2025, demonstrating the industry's rapid growth and the diverse needs of various projects. When budgeting, it's essential to not only consider initial costs but also long-term performance and reliability, which can significantly impact overall project success.

Performance metrics such as processing speed, power consumption, and integration capabilities often dictate the price of electronic boards. For instance, high-performance boards that utilize advanced microcontrollers can range from $50 to $200, while lower-end models typically cost less than $30.

Balancing your project’s specific requirements with your budget is paramount. A recent study by Allied Market Research highlighted that investing in a slightly more expensive board can yield better lifecycle returns due to enhanced durability and fewer maintenance costs—a vital consideration for projects with tight deadlines and budgets. Therefore, thorough research and careful analysis of both cost and performance will help ensure the best fit for your project needs.

Industry Trends: The Growing Demand for Customizable and Versatile Boards

In today's fast-paced technological landscape, the demand for customizable and versatile electronic boards is on the rise. Industries are increasingly seeking solutions that not only meet specific project needs but also offer flexibility and scalability. This trend is driven by the ongoing shift towards personalized technologies, where companies require boards that can adapt to various applications, ranging from consumer electronics to industrial automation.

To make the right choice for your project, consider these tips: First, assess the specific requirements of your application. Identify whether you need solid or inflatable options to determine the most suitable board type. Second, evaluate the compatibility with existing systems and how easily the board can integrate into your current operation. A board that offers seamless integration can prevent future roadblocks and facilitate smoother workflows.

Additionally, keep an eye on emerging industry trends. The growing emphasis on sustainability and eco-friendliness can guide your selection process. Opting for boards that use environmentally friendly materials can not only enhance your project’s appeal but also align with global sustainability goals. By staying informed and considering these factors, you can ensure that your chosen electronic board meets your needs effectively.

Related Posts

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

Mastering Electronic Board Manufacturing Techniques A Comprehensive Tutorial for Industry Professionals

-

Essential Tips for Identifying Top-Quality PCB Assembly Manufacturers

-

Digital Success in Electronic Board Manufacturing Strategies for Global Buyers

-

5 Best Strategies for Optimizing PCB Manufacturing Assembly Efficiency

-

Innovative Examples of Printed Circuit Assembly that Set the Industry Standard