Understanding the Challenges in Achieving Best PCB Assembly Quality

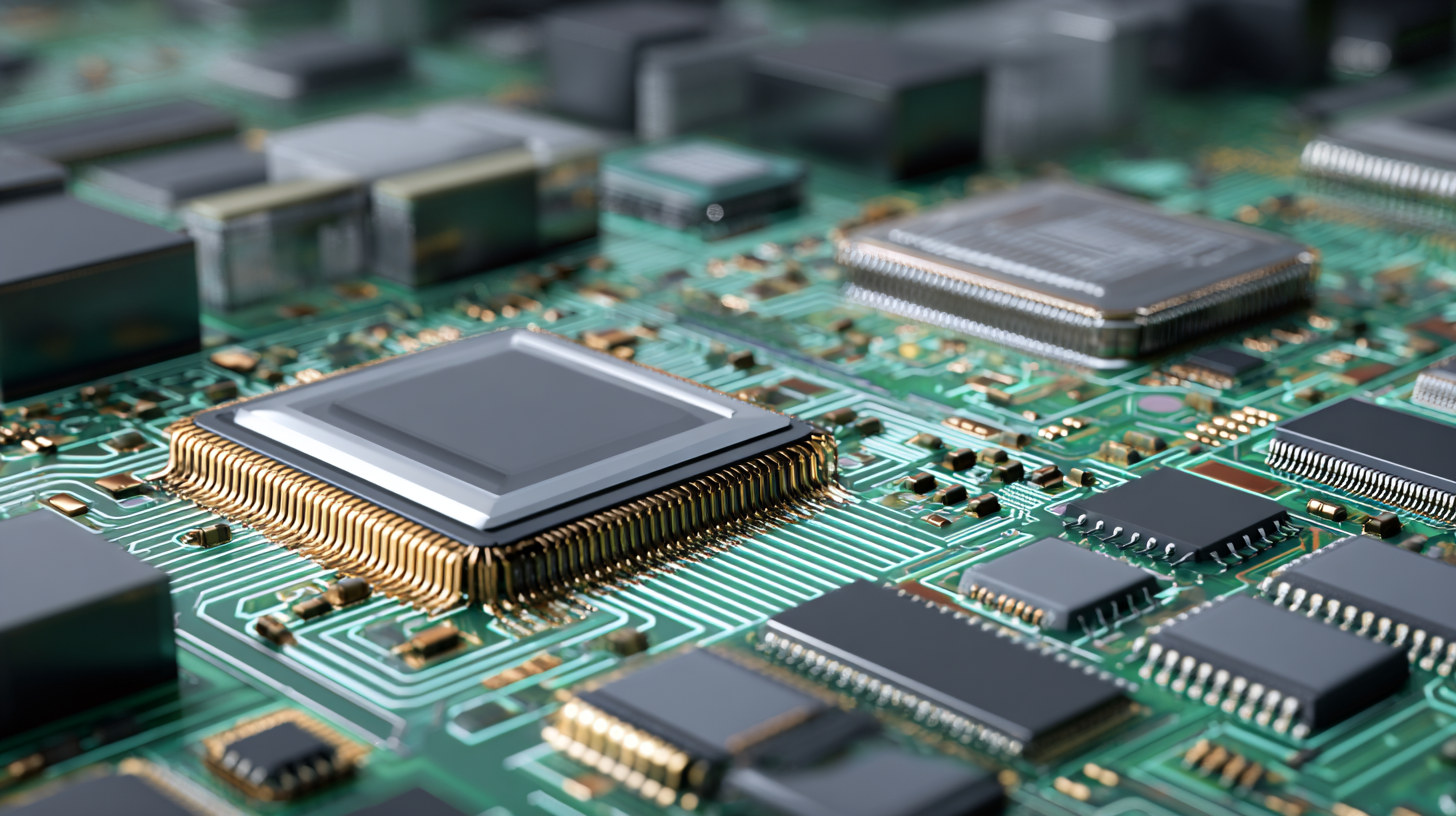

In the rapidly evolving landscape of electronics manufacturing, achieving the highest quality in pcb assembly has emerged as a critical challenge for companies striving to maintain a competitive edge. With the global PCB assembly market projected to reach $85.38 billion by 2025, ensuring that products meet stringent quality standards is paramount for manufacturers (Source: MarketsandMarkets). The increasing complexity of electronic designs, coupled with the pressure to reduce time-to-market, has underscored the need for robust quality assurance strategies.

Issues such as component misalignment, solder defects, and inadequate process controls can lead to significant cost implications, with reports indicating that poor quality in manufacturing can result in up to 30% of production costs being attributed to rework and scrap (Source: IPC). Therefore, understanding and addressing the challenges in achieving optimal pcb assembly quality is vital for organizations aiming to enhance product reliability and customer satisfaction.

The Importance of High-Quality PCB Assembly in Modern Electronics

In the realm of modern electronics, the significance of high-quality PCB assembly cannot be overstated. With the rapid advancements in technology demanding smaller, faster, and more efficient devices, the assembly of printed circuit boards (PCBs) has emerged as a critical aspect of electronics manufacturing. A well-assembled PCB ensures not only optimal performance but also longevity of the electronic product. Poor assembly can lead to frequent failures, which may translate into significant economic losses and diminished consumer trust.

Furthermore, high-quality PCB assembly strongly influences the overall reliability and functionality of electronic systems. As devices become more complex, the need for precision in components placement and soldering becomes paramount. Advanced techniques, such as automated optical inspection and X-ray imaging, are often employed to detect defects at early stages, thus improving the quality assurance process. Manufacturers who prioritize PCB assembly quality stand to gain a competitive advantage by delivering products that meet stringent industry standards, thereby meeting consumer demands for durability and reliability in a market that relies heavily on electronic innovation.

Key Challenges Affecting PCB Assembly Quality Standards

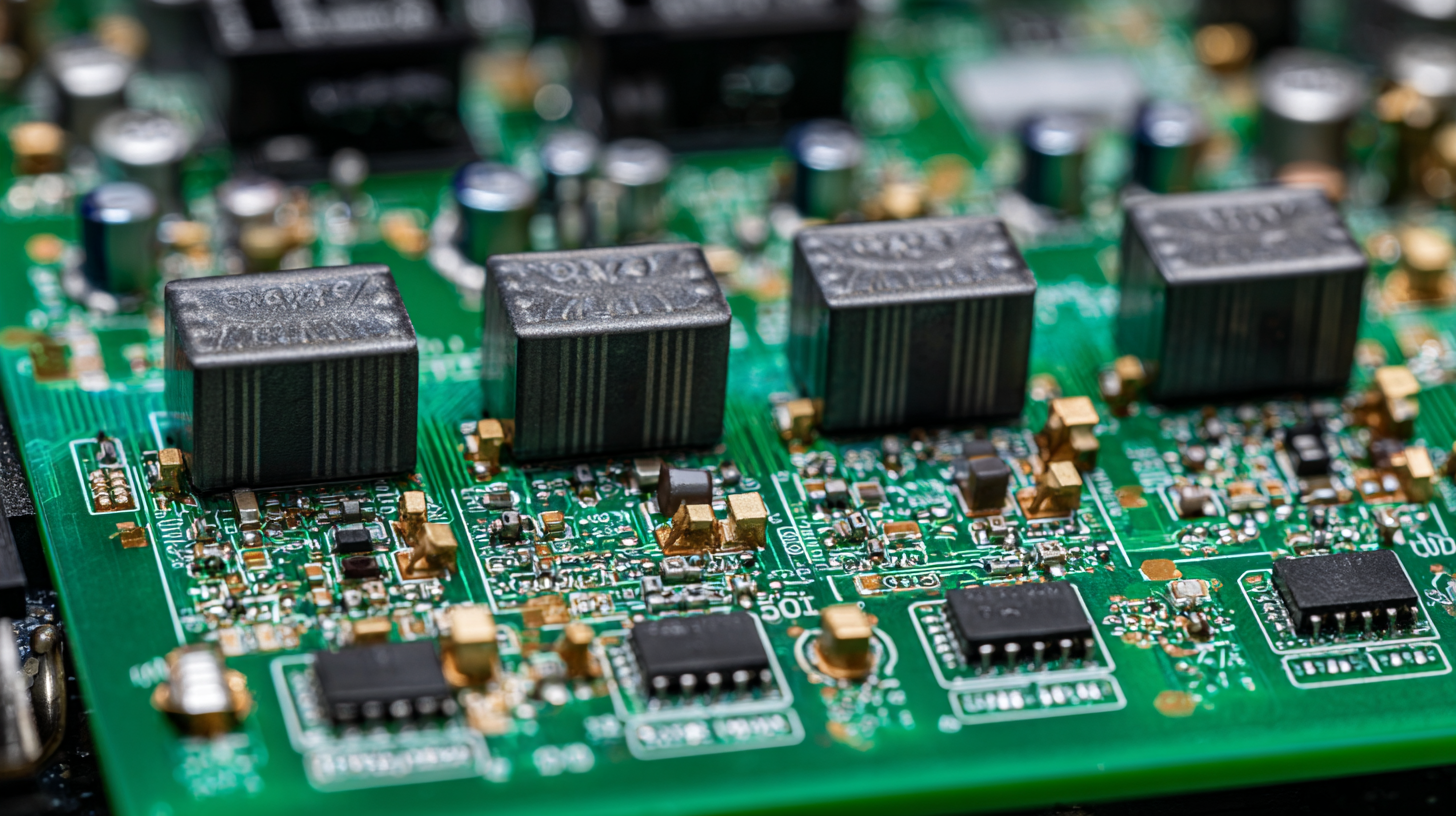

Achieving high-quality PCB assembly is fraught with challenges that can significantly impact the final product's performance and reliability. One of the primary challenges is the consistent alignment of components during the soldering process. Misalignment can lead to poor electrical connection, increasing the risk of device failure. Ensuring precision in automated assembly lines is crucial, and any deviation can result in costly reworks or scrappage of defective boards.

Another critical issue is managing the variability in component quality and specifications. With a vast array of suppliers and components available, ensuring that each part meets rigorous quality standards is essential to maintaining overall assembly quality. Inconsistent material quality can lead to soldering problems and affect the durability of the assembled boards. Continuous quality audits and supplier assessments are necessary to mitigate risks and enhance the end-product reliability. As PCB technology evolves, manufacturers must adapt to address emerging challenges, ensuring they meet or exceed quality standards.

Understanding the Challenges in Achieving Best PCB Assembly Quality

Strategies for Overcoming PCB Assembly Quality Issues

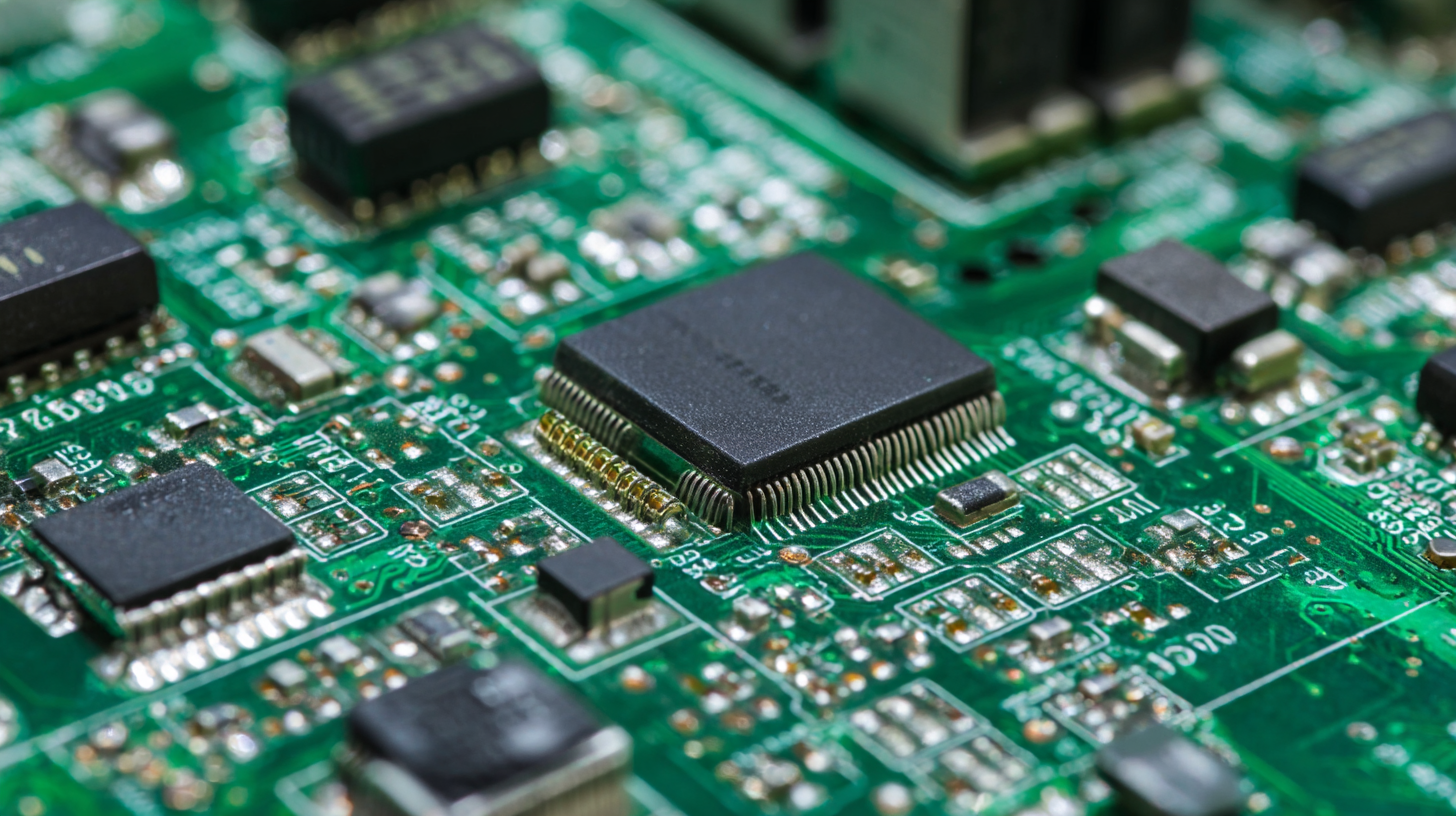

Achieving high-quality PCB assembly is a complex task that involves numerous challenges ranging from component selection to manufacturing processes. One of the primary strategies for overcoming these quality issues is to implement rigorous quality control measures throughout the production cycle. Regular inspections and a well-defined testing protocol can help identify defects early in the assembly process, ensuring that issues are rectified before they escalate into larger problems.

Another effective strategy is to invest in advanced technology and automation. Automated Optical Inspection (AOI) systems and X-ray inspection can greatly enhance the precision of the assembly process, reducing the risk of human error. By integrating these technologies, manufacturers can achieve finer details and higher accuracy in the assembly, which is crucial for maintaining PCB integrity. Additionally, proper training for staff on the latest assembly techniques and quality standards is essential to foster a culture of quality awareness and accountability within the organization. This multi-faceted approach not only addresses existing quality challenges but also lays a solid foundation for continuous improvement in PCB assembly processes.

The Role of Technology in Enhancing PCB Manufacturing Quality

As the demand for high-quality PCB assembly continues to rise, the role of technology in enhancing manufacturing processes becomes increasingly crucial. Modern advancements such as automated optical inspection (AOI) and advanced testing methodologies have significantly improved defect detection rates. According to a report by IPC, incorporating AOI can reduce assembly defects by up to 30%, leading to not only higher yield rates but also increased customer satisfaction.

Furthermore, the implementation of Industry 4.0 technologies, such as IoT and AI, empowers manufacturers to optimize their processes through real-time data analysis. Research from Deloitte indicates that companies utilizing these technologies can experience up to a 20% reduction in production costs, while also enhancing overall quality control. By leveraging predictive analytics, manufacturers can foresee potential issues and address them proactively, ensuring that the final PCB products meet stringent quality standards.

In addition, the integration of materials science innovations—like advanced solder materials and substrates—plays a pivotal role in enhancing assembly quality. A study by The Next Generation Manufacturing Canada shows that using high-performance materials can lead to lower thermal and mechanical stresses, thereby extending the lifespan of PCBs. Ultimately, these technological advancements are not just enhancing manufacturing efficiency but are also setting new benchmarks for quality in the PCB assembly industry.

Global Impact of PCB Quality on Supply Chain Efficiency

The quality of printed circuit boards (PCBs) plays a crucial role in the overall efficiency of the supply chain. In today's interconnected world, any deficiencies in PCB quality can lead to significant delays and increased costs. When a PCB fails to meet industry standards, it can cause ripple effects that impact production schedules, shipment timelines, and ultimately, customer satisfaction. Companies must understand these impacts to mitigate risks and promote a more efficient supply chain.

To ensure PCB quality, manufacturers should adopt rigorous testing protocols throughout the assembly process. This includes implementing automated optical inspection (AOI) to detect defects early on. Additionally, regular training for assembly line workers on quality standards can help maintain a high level of craftsmanship. Collaborating with reliable suppliers who share a commitment to quality can also streamline processes and reduce the potential for disruptions.

Another important tip is to utilize advanced quality management systems (QMS) that provide real-time data on PCB performance. These systems enable companies to identify trends and areas for improvement while facilitating proactive decision-making. By prioritizing PCB quality, businesses can enhance supply chain efficiency and position themselves favorably in a competitive market.