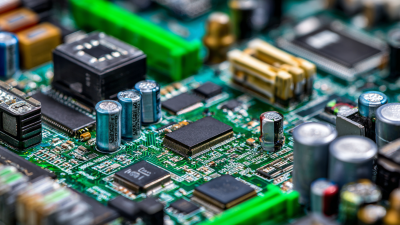

Top 10 Benefits of PCB Printing for Electronics Industry?

The electronics industry is rapidly evolving, and PCB printing is at the forefront of this transformation. A recent report by the Electronics Manufacturing Association indicates that the demand for PCB printing will grow by 8% annually. This impressive growth highlights the importance of innovative techniques in manufacturing. Experts suggest that effective PCB printing can significantly reduce time and costs in production.

John Smith, a leading expert in PCB technology, remarked, “Quality in PCB printing leads to efficiency in electronics manufacturing.” This statement captures the essence of why integrating advanced PCB printing methods can enhance overall product reliability. The benefits are not only cost-effective but also contribute to faster turnaround times and better design flexibility.

However, the implementation of PCB printing is not without challenges. Companies must navigate issues such as supply chain disruptions and quality control. These difficulties underline the need for continual improvement in processes. Embracing PCB printing can unlock opportunities, but companies must be prepared to tackle these challenges head-on. In this evolving field, staying adaptable is crucial for success.

Top 10 Benefits of PCB Printing for the Electronics Industry

PCB printing offers numerous advantages that greatly benefit the electronics industry. Efficient production is one key aspect. With advancements in printing technology, manufacturers can produce high-quality PCBs quickly. This speed allows companies to bring products to market faster, which is critical in a competitive landscape. Moreover, the precision of PCB printing reduces the likelihood of errors, minimizing costly rework.

Customization is another significant benefit. Businesses can tailor designs to meet specific needs. This flexibility is particularly useful for niche markets or unique projects. However, customization can sometimes lead to complexities in the design process. Engineers must balance creativity with practicality, ensuring designs are not just innovative but also manufacturable.

Sustainability plays an increasingly important role as well. Eco-friendly materials and processes are becoming more common in PCB printing. This shift helps reduce the environmental impact. Yet, it also poses challenges. Transitioning to greener practices requires investment and adaptation. Companies may struggle with initial costs while aiming for long-term benefits. Every advancement presents its own set of challenges, and reflection is necessary for continuous improvement.

Top 10 Benefits of PCB Printing for the Electronics Industry

| Benefit | Description |

|---|---|

| Cost-Effectiveness | PCB printing reduces manufacturing costs due to less waste and efficient materials usage. |

| Customization | Allows for tailored designs to meet specific project requirements and rapid prototyping. |

| Faster Production | PCB printing significantly speeds up the manufacturing process, leading to quicker time-to-market. |

| Reduced Errors | Automated processes minimize human error, enhancing the reliability of PCB designs. |

| High Precision | Modern printing techniques offer high precision in component placement and trace routing. |

| Material Variety | Supports a wide range of materials, including flexible and rigid substrates for diverse applications. |

| Environmental Benefits | Less waste and energy consumption make PCB printing a greener option compared to traditional methods. |

| Integration with Smart Technologies | Facilitates the integration of smart components like sensors and microcontrollers into PCBs. |

| Scalability | Easily scalable production processes allow for high-volume manufacturing without significant delays. |

| Improved Performance | Enhanced thermal management and better signal integrity lead to overall improved performance of PCB. |

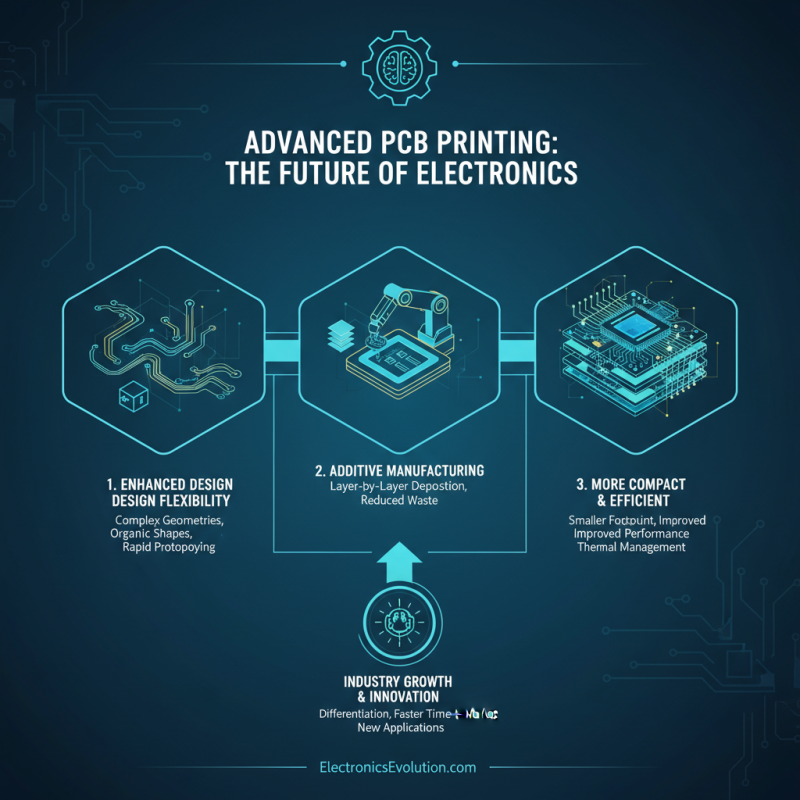

Enhanced Design Flexibility in PCB Production Techniques

The electronics industry has seen significant growth through advanced PCB printing techniques. Enhanced design flexibility is key in this evolution. With technologies like additive manufacturing, designers can create complex geometries that traditional methods struggle to achieve. This results in more compact and efficient boards, helping manufacturers to differentiate their products.

According to a report by IPC, over 50% of companies have adopted advanced PCB techniques to improve production speed and quality. Flexible PCB designs allow for integration into unconventional shapes, which is vital for modern devices. Devices like smartphones and wearables benefit immensely from this flexibility. The ability to customize quickly remains a double-edged sword. While it fosters innovation, it can also lead to challenges in quality control.

Moreover, these innovative designs are often more expensive. Many companies risk overspending on features that their target market may not appreciate. Design teams must balance creativity and cost. Adapting to consumer needs while managing production costs proves to be an ongoing challenge. Flexibility in design is a powerful asset but requires thoughtful implementation and continuous assessment.

Reduced Manufacturing Costs through Efficient PCB Printing

The electronics industry is undergoing a transformation with PCB printing. One primary benefit is reduced manufacturing costs. Efficient PCB printing streamlines the entire production process. According to a recent report by IPC, manufacturers can reduce costs by up to 30% using advanced PCB printing techniques. This reduction is crucial in a competitive market.

Moreover, advanced PCB printing allows for shorter production times. Traditional methods often lead to delays and added expenses. By employing digital processes, companies can prototype and produce PCBs in a fraction of the time. This boosts overall efficiency and enables quicker time-to-market for new products.

Tips: Evaluate your current PCB production methods. Look for areas where costs can be reduced. Invest in training for your team to maximize the benefits of new printing technologies.

In addition, consider the flexibility of PCB printing. It provides options for low-volume runs and custom designs. Such adaptability can lead to innovative products. Yet, be aware that depending solely on new technology might neglect tried-and-true methods. Balancing innovation with reliability is essential for success.

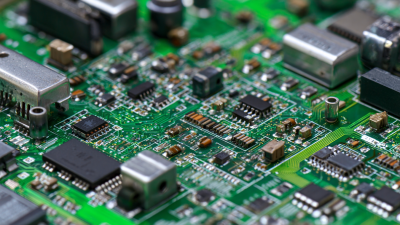

Top 10 Benefits of PCB Printing for Electronics Industry

Improved Production Speed with Advanced PCB Printing Technologies

Advanced PCB printing technologies significantly enhance production speed in the electronics industry. Reports indicate that these technologies can reduce manufacturing time by up to 50%. Faster processes lead to shorter lead times, which is critical in a fast-paced market. Companies can respond quickly to changes in demand and trends. This flexibility boosts competitive advantage.

Moreover, advanced PCB printing techniques allow for greater design complexity. Manufacturers can produce intricate designs that were previously time-consuming or impossible. For instance, multilayer PCBs are now more accessible. The ability to incorporate more features in a compact design can lead to innovation. According to industry analyses, about 75% of companies that adopted these technologies report improved product quality.

However, the transition to advanced printing methods is not without challenges. Initially, the investment costs for new printing equipment can be high. Some facilities may face a steep learning curve. Training employees is essential but can consume valuable time. Despite these hurdles, the potential benefits of faster production and enhanced designs are driving many manufacturers to adapt. This shift is reshaping the landscape of electronics manufacturing, making it more efficient and innovative.

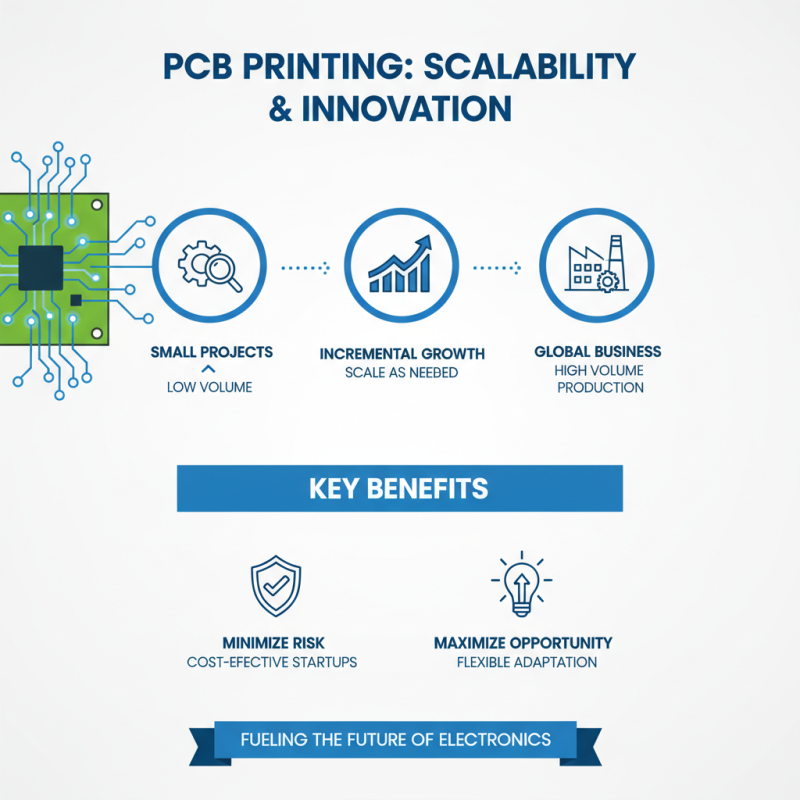

Incremental Scalability for Small to Large Volume PCB Orders

The electronics industry thrives on innovation and efficiency. PCB printing supports this by allowing incremental scalability for orders. Small projects can start with low volumes and grow as needed. This flexibility is crucial for startups and established businesses alike. It minimizes risk while maximizing opportunities.

Tips: Assess your production needs carefully. Determine if you require small batches or larger quantities. Balancing volume with demand can save costs.

As production scales, quality must remain paramount. Increasing order sizes can expose flaws in designs. Regular quality checks throughout the production process are essential. Neglecting these could lead to significant setbacks.

Tips: Implement a feedback loop for design improvements. Continuous evaluations ensure that products meet standards.

Embracing PCB printing enhances adaptability. The capacity to move from prototype to mass production is a game changer. However, businesses must manage resources wisely. Decisions made in haste often lead to oversights. Thoughtful planning is vital for sustainable scaling.

Conclusion

PCB printing has revolutionized the electronics industry by offering numerous advantages that enhance production efficiency and sustainability. One of the significant benefits is the enhanced design flexibility it provides in PCB production techniques, allowing for intricate and customized designs to meet specific requirements. Additionally, PCB printing reduces manufacturing costs by streamlining processes and minimizing material waste, which is essential for maintaining profitability in a competitive market.

Moreover, advanced PCB printing technologies contribute to improved production speed, enabling manufacturers to meet tight deadlines without compromising quality. This method also supports incremental scalability, making it suitable for both small and large volume PCB orders. Importantly, the adoption of eco-friendly PCB printing practices promotes sustainability, aligning with the industry's growing focus on environmental responsibility. Overall, PCB printing not only optimizes production workflows but also fosters a more sustainable approach to electronics manufacturing.

Related Posts

-

Ultimate Checklist for Selecting the Best PCB Fabrication Services Worldwide

-

10 Essential PCB Printing Techniques You Need to Know

-

The Future of Smart PCB Board Technology in Electronics

-

Mastering Electronic Board Manufacturing Techniques A Comprehensive Tutorial for Industry Professionals

-

Essential Checklist for Choosing the Best PCB Fabrication Services Based on Industry Standards

-

Why Are PCB Circuit Boards Essential in Modern Electronics?