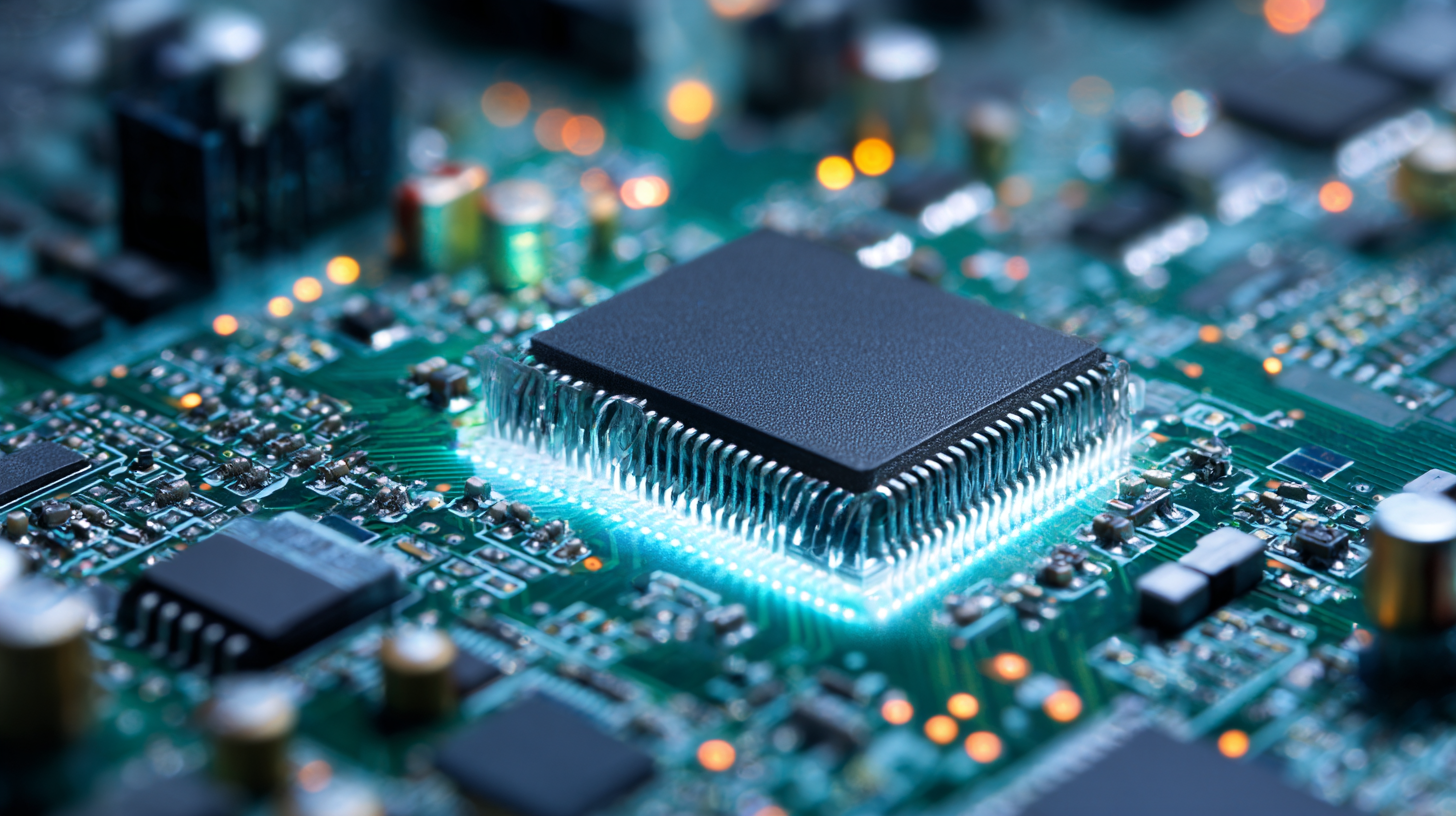

2025 Top 10 Trends in Printed Circuit Board Assembly: Industry Growth & Innovations

As we look toward 2025, the landscape of printed circuit board assembly (PCBA) is evolving at an unprecedented pace. The global PCBA market is projected to reach $100 billion by 2024, with a compound annual growth rate (CAGR) of 5.5% from 2020 to 2025, according to a report by Market Research Future. This growth is driven by technological advancements, increasing demand for consumer electronics, and the rise of smart appliances, making it a pivotal time for stakeholders in the industry to adapt and innovate.

Industry experts, such as Dr. Jane Smith, a leading authority in electronic manufacturing, emphasize the importance of embracing new trends as they unfold. Dr. Smith states, "The future of printed circuit board assembly lies in our ability to integrate automation and artificial intelligence into our processes, making them faster and more efficient while significantly reducing errors." This perspective highlights the urgent need for companies to invest in cutting-edge technologies to stay competitive.

In this rapidly changing environment, understanding the top trends in PCBA will equip businesses with the insights needed to navigate challenges and seize new opportunities. From advancements in materials to shifts in consumer preferences, the next few years promise to be transformative for the printed circuit board assembly industry.

Key Innovations Shaping Printed Circuit Board Assembly in 2025

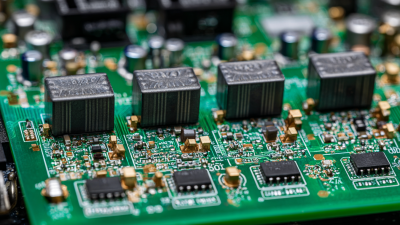

In 2025, the landscape of Printed Circuit Board (PCB) assembly is set to be transformed by several key innovations that will enhance efficiency and reliability. One of the most significant advancements is the proliferation of automated assembly processes powered by artificial intelligence. These AI-driven systems are capable of learning and adapting to varying production scenarios, enabling manufacturers to optimize workflows and reduce error rates, thereby increasing overall productivity.

Additionally, the integration of flexible and hybrid materials in PCB assembly is reshaping design possibilities. These materials not only allow for more compact and lightweight electronic devices but also improve durability against environmental stressors. Innovations in 3D printing technology are also making waves, allowing for rapid prototyping and customization of PCBs, which enhances design flexibility. Together, these innovations are paving the way for smarter, more resilient electronic products that meet the evolving demands of industries across the board.

Sustainable Practices Driving Environmental Responsibility in PCB Manufacturing

The printed circuit board (PCB) manufacturing industry is undergoing a significant transformation as it shifts towards more sustainable practices. Environmental responsibility is becoming a key driver in PCB assembly, pushing manufacturers to rethink their processes and materials. Innovations in eco-friendly materials, such as biodegradable substrates and lead-free solder, are being adopted to minimize environmental impact. These practices not only help in reducing waste but also enhance the overall sustainability of electronic products.

Additionally, companies are increasingly investing in energy-efficient production methods and waste reduction strategies. Techniques such as recycling and reusing materials can significantly lower the carbon footprint associated with PCB manufacturing. By implementing closed-loop systems, manufacturers can ensure that resources are optimized, and harmful emissions are reduced. This shift reflects a broader trend within the electronics industry, where sustainable practices are not just a regulatory requirement but a competitive advantage that appeals to environmentally conscious consumers. As the industry evolves, the focus on environmental responsibility will undoubtedly lead to more innovative solutions and a greener future for PCB manufacturing.

The Role of Automation and AI in Enhancing PCB Assembly Efficiency

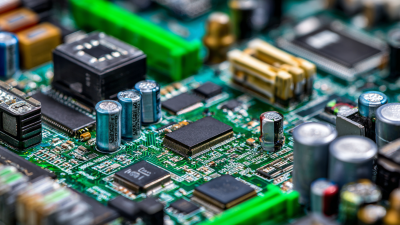

The printed circuit board (PCB) assembly industry is undergoing a significant transformation driven by advancements in automation and artificial intelligence (AI). As manufacturers strive to enhance efficiency and reduce production costs, automation technologies are being increasingly integrated into PCB assembly processes. Automated machines can handle repetitive tasks with precision and speed, minimizing human error and ensuring higher quality standards. This allows companies to scale up their production while maintaining consistency in their output.

In addition to automation, AI is playing a crucial role in optimizing PCB assembly workflows. By leveraging machine learning algorithms, manufacturers can analyze vast amounts of production data to identify patterns and predict potential issues before they arise. This proactive approach enables companies to streamline their operations, implement predictive maintenance, and reduce downtime. Moreover, AI-driven quality control systems can detect defects in real-time, further ensuring the integrity of the assembled boards. As these technologies continue to evolve, the PCB assembly industry is expected to witness unprecedented levels of efficiency and innovation in the coming years.

Emerging Materials and Technologies Revolutionizing Circuit Board Design

The realm of printed circuit board (PCB) assembly is undergoing a significant transformation driven by emerging materials and technologies. As we approach 2025, industry leaders are emphasizing the adoption of advanced materials such as high-frequency laminates and flexible PCBs. According to a recent report from IPC, the global PCB market is projected to reach $79.5 billion by 2025, underscoring the demand for innovative design solutions that can accommodate the rapid advancement of electronic devices.

The incorporation of technologies like additive manufacturing and automated assembly processes is also setting the stage for groundbreaking changes in circuit board design. For instance, research by MarketsandMarkets forecasts that the additive manufacturing market for electronics will grow to $3 billion by 2026, highlighting the shift toward more efficient, customizable production techniques. As manufacturers explore these innovations, the potential for lighter, more compact, and higher-performing PCBs is becoming increasingly achievable.

Tip: When considering your next PCB project, evaluate the benefits of flexible materials that can withstand the demands of miniaturization and flexibility in modern electronics. Additionally, staying updated on the latest automation technologies can optimize your assembly processes, ultimately saving time and reducing production costs.

Market Trends Influencing PCB Assembly Demand and Growth Strategies in 2025

In 2025, the trends influencing the Printed Circuit Board (PCB) assembly market are set to be significantly shaped by the rapid advancements in AI technologies and the increasing demand for sophisticated electronics in various sectors. The OEM electronics assembly market is anticipated to expand, with hardware and software types witnessing substantial growth driven by burgeoning applications in automotive, communications, computing, consumer electronics, industrial, medical, and aerospace industries. This shift not only points to a change in consumer behavior but also highlights the need for innovative manufacturing techniques to support these sectors.

As the demand for smart devices and AI-driven solutions escalates, the PCB industry is expected to see a remarkable surge in production and innovation. The introduction of advanced robotics within manufacturing processes and the sustained integration of AI capabilities will likely lead to enhanced efficiency and precision in PCB assembly. With favorable market conditions, particularly in regions experiencing technological advancements, stakeholders are encouraged to adopt growth strategies that leverage cutting-edge materials and methods to meet the evolving needs of end-users. This promising landscape indicates that by 2025, the PCB assembly sector will play a crucial role in underpinning the robust growth trajectory of the broader electronics market.

2025 PCB Assembly Trends: Industry Growth & Innovations

This chart illustrates the top trends influencing the growth of PCB assembly in 2025, highlighting the percentage of influence each trend has on the market. Automation, miniaturization, and IoT integration are leading the way in shaping the future of PCB assembly.

Related Posts

-

How to Choose the Best PCB Fabrication Partner for Global Supply Chain Success

-

Understanding PCB Printing Techniques and Their Impact on Modern Electronics Efficiency

-

Exploring Innovations in Printed Circuit Board Technology at the 138th Canton Fair 2025

-

Understanding the Challenges in Achieving Best PCB Assembly Quality

-

Common Issues Faced in High Density PCB Circuit Design

-

Mastering Electronic Board Manufacturing Techniques A Comprehensive Tutorial for Industry Professionals