2025 Top 10 Innovations in PCB Electronics You Must Know

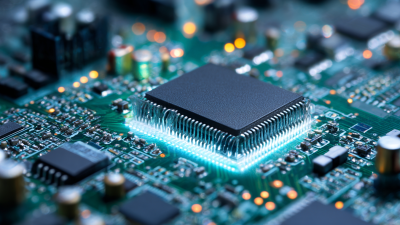

As the demand for more advanced and efficient electronics continues to rise, the realm of PCB electronics is at the forefront of innovation, driving significant advancements in technology. According to a recent report by Allied Market Research, the global PCB market is expected to reach $100 billion by 2026, growing at a CAGR of 3.7% from 2019. This growth is attributed to the increasing miniaturization of electronic devices and the proliferation of smart technologies. In this rapidly evolving landscape, staying informed about the latest trends and innovations in PCB electronics is essential for industry professionals.

Dr. Emily Carter, a renowned expert in the field of PCB technology, emphasizes the importance of innovation in this sector: "The future of PCB electronics hinges on our ability to adapt and integrate cutting-edge technologies that enhance performance and reduce environmental impact." As we approach 2025, the top innovations in PCB electronics are not just reshaping the manufacturing processes but also redefining the capabilities and applications of electronic devices across various industries. This article will explore the ten most significant innovations that you must know, setting the stage for the next generation of PCB electronics.

Future-Focused: How Flexible PCBs Are Transforming Electronics Design

Flexible printed circuit boards (PCBs) are revolutionizing electronic design by enabling new applications that were previously deemed impossible. According to a report by Market Research Future, the global flexible PCB market is expected to reach approximately $30 billion by 2025, growing at a compound annual growth rate (CAGR) of about 10.4%. This growth is driven by the increasing demand for lightweight and compact electronic devices across various industries, including consumer electronics, automotive, and healthcare.

The ability of flexible PCBs to conform to irregular shapes allows designers to create more innovative products, including wearable technology and portable medical devices.

Moreover, flexible PCBs contribute to enhanced performance and reliability. A comparative study by IPC found that flexible circuits can significantly reduce weight and assembly time while offering better thermal management compared to traditional rigid boards. With their excellent electrical performance and durability, they are now integral in applications that require high-density interconnections, such as smartphones and tablets. As manufacturers prioritize miniaturization, flexible PCBs stand out as a key technology that aligns perfectly with the trends of the future, paving the way for smarter and more efficient electronic solutions.

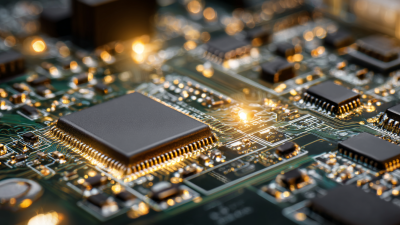

Revolutionizing Thermal Management: Innovations to Keep Your PCBs Cool

Thermal management is becoming increasingly crucial in the evolving landscape of PCB electronics, especially as devices demand higher performance and efficiency. Recent innovations are focusing on effective cooling solutions to tackle the heat generated by more complex electronic systems. For instance, the introduction of diamonds and laser technology has emerged as a groundbreaking method for enhancing chip cooling in the AI sector. This advancement is essential as high-performance computing continues to escalate, leading to increased thermal challenges.

To optimize thermal management in PCB design, consider using advanced materials and efficient layout techniques. Incorporating heat sinks or using thermal interface materials can significantly improve heat dissipation, prolonging the lifespan of your devices. Additionally, the integration of Lab-on-PCB technology demonstrates a notable trend where bio-microsystem integration not only reduces size but also enhances thermal performance through innovative designs.

As we look toward 2025, it’s clear that innovations in thermal management will revolutionize PCB technology. Staying informed about these trends ensures that engineers and manufacturers can implement solutions that enhance performance while managing the thermal constraints of increasingly sophisticated electronics. Remember, effective thermal management is not just about cooling; it’s also about optimizing overall system efficiency and reliability.

Sustainability in Electronics: Eco-Friendly Materials for PCB Manufacturing

In the realm of PCB manufacturing, sustainability has become a pivotal focus area as the industry grapples with its environmental footprint. With an estimated 1.6 million tons of electronic waste generated globally each year, it is imperative to seek eco-friendly materials that can mitigate these impacts. Innovative alternatives, such as biodegradable substrates and fully recyclable components, are being adopted by industry leaders to align with international standards for environmental stewardship. Recent reports indicate that the market for sustainable materials in electronics is expected to grow by over 15% annually, underscoring a significant shift towards greener manufacturing processes.

To embrace this sustainable wave, PCB manufacturers can implement several strategies. One effective tip is to conduct a life cycle assessment (LCA) for materials used in circuit boards. This assessment helps in determining the environmental impacts associated with each stage, from raw material extraction to disposal. Additionally, exploring partnerships with suppliers who specialize in sustainable materials can streamline the transition towards more eco-friendly practices. Engaging in continuous education about emerging sustainable technologies will also help businesses stay ahead and address growing consumer demand for environmentally responsible products.

Furthermore, utilizing technologies like additive manufacturing can further enhance sustainability efforts by reducing material waste during the production of PCBs. As the industry continues to evolve, staying informed about cutting-edge innovations and sustainable practices will be essential for any manufacturer looking to thrive in the competitive electronics market.

Enhancing Performance: The Role of AI in PCB Design and Production

The integration of artificial intelligence (AI) into printed circuit board (PCB) design and production is revolutionizing the electronics industry. AI algorithms are capable of analyzing vast amounts of data, allowing for enhanced decision-making in the design phase. By automating complex calculations and simulations, designers can optimize board layouts in a fraction of the time previously required. This efficiency not only accelerates product development cycles but also minimizes human error, leading to higher quality and more reliable PCBs.

In the production phase, AI-driven systems monitor manufacturing processes in real-time, ensuring adherence to quality standards and reducing waste. Machine learning models can predict equipment failures and maintenance needs, thus improving operational efficiency. Furthermore, AI enhances customization options, enabling manufacturers to respond swiftly to changes in market demands or customer preferences. As the PCB industry continues to embrace these advancements, AI will play a pivotal role in driving innovation, ultimately leading to smarter, more efficient electronic products.

Miniaturization Trends: Advancements in High-Density Interconnect Technology

The electronics industry is experiencing a significant transformation spurred by miniaturization trends, particularly in the realm of high-density interconnect (HDI) technology. With an increasing demand for compact and efficient devices, the HDI PCB market is projected to surpass USD 19.59 billion by 2025. This surge is largely attributed to the industry's push for smaller and more reliable electronic components that enhance performance while saving space. The integration of advanced substrates has become crucial in enabling these innovations.

Moreover, the substrate-like PCB market is estimated to achieve USD 8.9 billion by 2034, reflecting a robust compound annual growth rate (CAGR) of 19.5% throughout the forecast period. This growth is underpinned by advancements that allow for higher component density and improved signal integrity, further pushing the boundaries of miniaturization. The molded interconnect device market, poised to expand at approximately 10% CAGR through 2032, underscores the industry's focus on creating devices that seamlessly integrate functionalities into diminutive packages, driving both efficiency and reliability across various sectors.

2025 Top 10 Innovations in PCB Electronics: Miniaturization Trends

Related Posts

-

Exploring Innovations in Printed Circuit Board Technology at the 138th Canton Fair 2025

-

Common Issues Faced in High Density PCB Circuit Design

-

How to Choose the Best PCB Fabrication Partner for Global Supply Chain Success

-

2025 Top 10 Trends in Printed Circuit Board Assembly: Industry Growth & Innovations

-

Understanding PCB Printing Techniques and Their Impact on Modern Electronics Efficiency

-

Revolutionizing Industries: The Future of PCB Electronics in Sustainable Technology